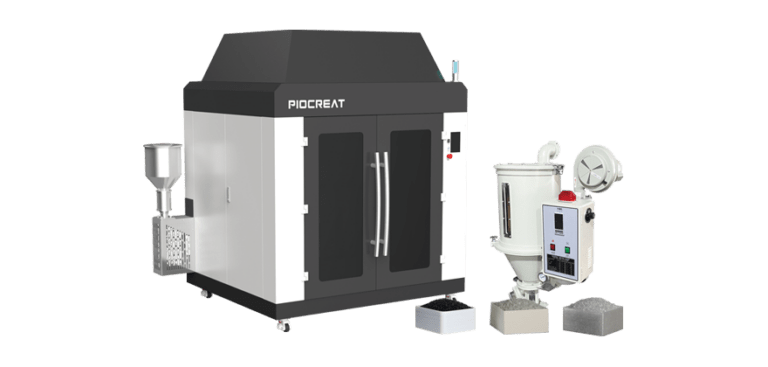

G12 Overview

At its core, the G12 pellet 3d printer leverages FGF technology where material is extruded layer by layer to create intricate three-dimensional objects. However, unlike FDM printers that rely on filaments, the G12 utilizes plastic pellets as its primary feedstock. This distinction is pivotal as it significantly reduces production costs by eliminating the need for filament production processes.

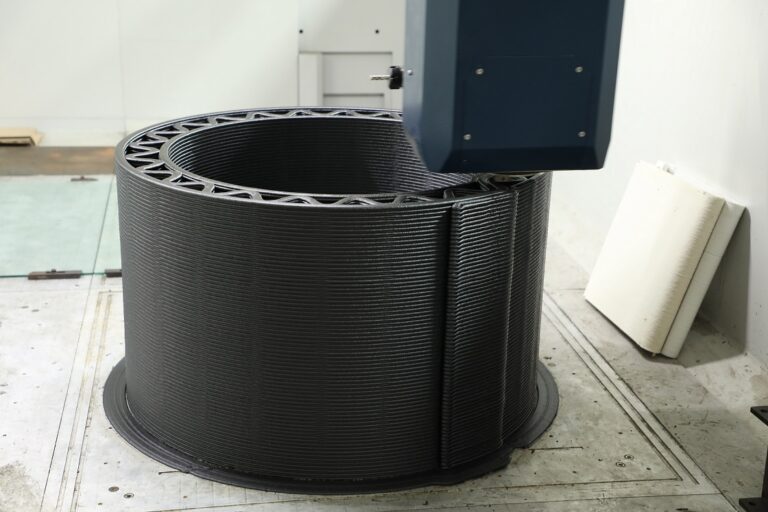

The G12 boasts impressive specifications, featuring a substantial printing size of 1200 x 1000 x 1000 mm, providing ample space for large-scale projects. Equipped with a single screw nozzle design, the printer ensures uniform extrusion force, facilitating high-quality prints with precision and consistency across various materials.

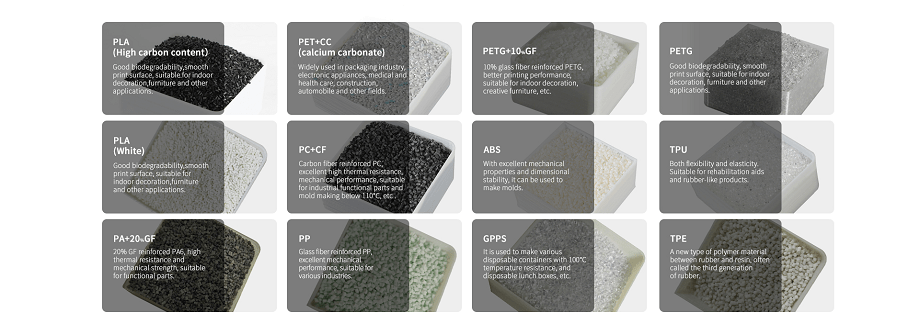

With a nozzle temperature reaching up to 450°C and a bed temperature of ≤130°C, the G12 accommodates a diverse range of materials, including PLA, PETG, ABS, TPU, and composite materials. The G12 can print with a slice thickness ranging from a minute 0.2 right through to a chunky 1.5mm, and can use nozzles ranging from 0.6~4mm diameter, allowing for fine details, or large flow rates (up to 5kg per hour). The G12 can cater for a range of granule sizes too, ranging from 2~5mm.

You can see a selection of compatible pellets in the graphic below.

One of the standout features of the G12 is its versatility in accepting multiple file formats such as STL, OBJ, AMF, and 3DMF, coupled with convenient file transfer options via USB or storage card. Moreover, the printer supports multiple operating systems, including Windows, MAC, and Linux, ensuring compatibility and ease of use across different platforms.

The G12 excels in delivering rapid production speeds, with printing velocities reaching up to 100mm/s, significantly reducing lead times for manufacturing processes. This enhanced efficiency is further augmented by intelligent laser ranging, the leveling time can be significantly shortened and the leveling accuracy can be improved; Not only ensure the real-time and high safety of the leveling operation under the high temperature platform, but also avoid interference with the model during the printing process.

To Summarize

The G12 Pellet 3D Printer represents a huge leap in cost-effective industrial additive manufacturing, redefining the landscape with its cost-effectiveness, speed, and environmental consciousness.

With its advanced features, expansive printing capabilities, and commitment to sustainability, the G12 sets a new standard for industrial-grade 3D printing technology, empowering industries to innovate and create with unparalleled efficiency and precision.