Table of Contents

Dental 3D printing is revolutionizing the dental industry, offering unparalleled precision, efficiency, and customization. As dental practices and labs increasingly adopt this technology, the landscape of dentistry is transforming. This article explores the impact of dental 3D printing, the types of printers used, the materials involved, and the benefits for dental professionals. We’ll also highlight the best dental 3D printers for dental labs.

Is 3D Printing the Future of Dentistry?

3D printing is rapidly becoming a cornerstone of modern dentistry. By enabling the production of highly accurate and customized dental products, 3D printing is streamlining workflows and improving patient outcomes. From dental implants and crowns to surgical guides and orthodontic models, the applications of 3D printing in dentistry are vast and varied.

The ability to produce dental products in-house reduces the need for outsourcing, saving time and costs. Additionally, digital workflows minimize human error, leading to more precise and reliable results. As technology advances, the adoption of dental 3D printing is expected to grow, solidifying its role as the future of dentistry.

What Type of Dental 3D Printers Are Used in Dentistry?

Several types of 3D printers are utilized in dentistry, each with unique capabilities and applications. The main types include:

Stereolithography (SLA) Printers

These printers use a laser to cure liquid resin into solid objects. SLA printers are known for their high resolution and accuracy, making them ideal for producing detailed dental models and custom implants.

Digital Light Processing (DLP) Printers

DLP printers also use light to cure resin, but instead of a laser, they use a digital light projector. This allows for faster print times while maintaining high accuracy, making DLP printers suitable for producing dental crowns, bridges, and surgical guides.

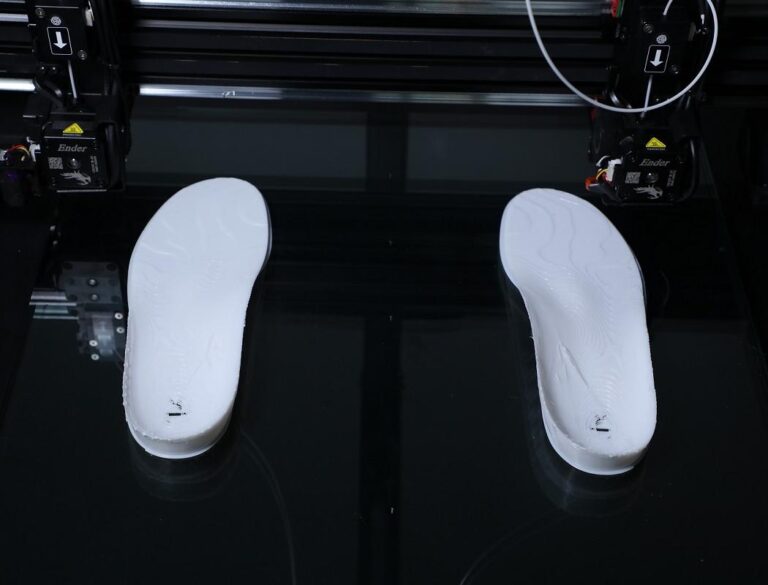

Fused Deposition Modeling (FDM) Printers

FDM printers extrude thermoplastic material layer by layer to build objects. While not as precise as SLA or DLP printers, FDM printers are cost-effective and can be used for creating orthodontic models and other larger dental appliances.

Selective Laser Sintering (SLS) Printers

SLS printers use a laser to fuse powdered material into solid objects. These printers are capable of producing strong and durable dental products, such as metal frameworks for dentures and orthodontic appliances.

What Material is Used in Dental 3D Printing?

The materials used in dental 3D printing must be biocompatible, durable, and capable of producing precise results. Common materials include:

Resin

Dental resins are widely used for creating crowns, bridges, surgical guides, and models. Resins come in various formulations, including biocompatible resins for direct use in the mouth and more rigid resins for durable dental appliances.

Metal

Metals like titanium and cobalt-chrome are used for producing strong and long-lasting dental implants and frameworks. Metal 3D printing is often used in conjunction with SLS technology to create intricate and durable components.

Thermoplastics

Materials like PLA and ABS are used in FDM printing for creating orthodontic models and other non-permanent dental appliances. These materials are easy to print with and cost-effective.

Ceramics

Ceramic materials are used for producing dental crowns and bridges that closely mimic the appearance and functionality of natural teeth. Ceramic 3D printing requires specialized equipment and expertise.

What Are the Benefits of 3D Printing for Dentists?

Innovation

The flexibility of 3D printing allows for the rapid prototyping and testing of new dental products and techniques. This innovation drives the advancement of dental care, leading to better patient outcomes.

Customization

3D printing enables the creation of highly customized dental products tailored to each patient’s unique anatomy. This customization improves the fit, comfort, and functionality of dental appliances and implants.

Cost-Effectiveness

By producing dental products in-house, dentists can save on outsourcing costs and reduce material waste. 3D printing also allows for the use of cost-effective materials, further lowering expenses.

Precision

The digital nature of 3D printing ensures a high level of accuracy in the production of dental products. This precision leads to better-fitting dental appliances and implants, reducing the need for adjustments and remakes.

Speed

3D printing significantly reduces the time required to produce dental products. Traditional methods can take weeks, whereas 3D printing can produce the same items in a matter of hours. This speed allows for faster treatment times and improved patient satisfaction.

Best Dental 3D Printers for Dental Labs

Choosing the right 3D printer is crucial for achieving optimal results in dental labs. Two standout models are:

DJ89 PLUS 8K 10.3″ LCD 3D Printer

- Top cost-effective resin 3D printer for dental industries

- 29μm Pixel Size: Delivers unmatched print clarity and detail, ensuring precise reproduction of dental products.

- Heating Chamber: Maintains consistent temperature for optimal printing conditions, enhancing the quality of the printed items.

- Automatic Feeding: Simplifies the printing process and reduces manual intervention, increasing efficiency.

- Stable Z-axis Structure: Provides precise and reliable prints, crucial for producing high-quality dental appliances and implants.

- Excels in dentistry with unmatched productivity

- Adjustable Light Intensity: Ranges from 6000-20000uw/cm², ensuring quick, high-quality prints for professionals.

- Speeds up to 80mm/h: Enables rapid production of dental products, reducing turnaround time.

- High Speed Release Film: Improves printing efficiency by reducing the time required for layer separation.

- Light Engine Life 30,000+ Hours: Ensures long-term reliability and consistent performance.

- Stable Z-axis Structure: Provides consistent and precise printing, essential for dental applications.

Both models are designed to meet the demanding requirements of dental professionals, offering the precision, speed, and reliability needed for successful dental procedures.

Conclusion

Dental 3D printing is revolutionizing the dental industry, offering significant benefits in terms of speed, precision, cost-effectiveness, and customization. By adopting advanced 3D printing technology, dental practices and labs can produce high-quality dental products in-house, reducing reliance on external suppliers and improving patient care.

As technology continues to evolve, the applications and benefits of dental 3D printing will only expand, further solidifying its role in modern dentistry. Embracing this technology not only enhances the quality of dental care but also drives innovation, leading to better patient outcomes and satisfaction.