Choosing the Right 3D Printer for Dentistry

piocreat3d

on

October 10, 2024

The field of dentistry has experienced significant advancements through 3D printing technology, enabling faster, more precise, and cost-effective solutions for producing dental models, surgical guides, and even full dentures. By investing in the right 3D printer, dental professionals can improve patient experiences, reduce costs, and increase productivity in both labs and clinics.

In this post, we’ll cover the key technologies and criteria to consider when selecting a dental 3D printer, examine various applications for dental 3D printing, and highlight some of Piocreat’s top models for dental professionals.

Dental 3D Printing Technologies Overview

In dental 3D printing, three primary technologies are commonly used: LCD (Liquid Crystal Display) Printing, DLP (Digital Light Processing) Printing, and SLA (Stereolithography) Printing. Each technology offers unique benefits depending on the application requirements in dental labs and clinics.

LCD (Liquid Crystal Display) Printing: Known for its affordability and high resolution, LCD printing uses an LCD panel to selectively cure resin, layer by layer. It’s a popular choice for high-detail work such as orthodontic and restorative models, offering cost-effective solutions without sacrificing quality.

DLP (Digital Light Processing) Printing: DLP printing projects an image of each layer onto the resin using a digital projector, allowing for faster print times than LCD while maintaining high precision. DLP printers are commonly used in dental applications requiring speed and accuracy, such as surgical guides and implant models.

SLA (Stereolithography) Printing: SLA technology uses a UV laser to precisely cure liquid resin layer by layer. Known for its high accuracy and smooth surface finish, SLA is ideal for applications needing exceptional detail, such as high-quality crowns, bridges, and custom prosthetics. Although it’s generally slower than DLP, SLA offers unmatched surface quality, making it popular for creating intricate dental components.

SLA, LCD, and DLP printing each have strengths, and selecting the best technology depends on specific dental needs, balancing cost, precision, and speed requirements.

Dental 3D Printer Comparison Criteria

To choose the right 3D printer for dental applications, consider the following key criteria:

1. Print Speed

Print speed is crucial in a busy dental lab or clinic environment, as faster production enables quicker turnarounds for patient-specific models. For high-throughput needs, look for printers capable of speeds up to 80mm/h, like the D150 from Piocreat, which is designed to handle large production volumes with efficiency.

2. Ease of Use

User-friendly operation is essential for saving time and reducing the learning curve, especially in dental clinics where team members may have varying levels of technical expertise. Features like automatic feeding and heating chambers improve ease of use by ensuring a consistent workflow, reducing downtime, and minimizing manual intervention.

3. Accuracy and Precision

Dentistry requires highly accurate models, especially for orthodontics, surgical guides, and restorations. Look for 3D printers with high-resolution capabilities, such as 29μm pixel size in the DJ89 PLUS, which ensures that every detail is captured for precise fitting and performance.

4. Material Options and Availability

The ability to print with a variety of resins is critical in dentistry. Each type of resin is specialized for different applications, from bio-compatible materials for surgical guides to flexible materials for try-ins. The availability of FDA-approved dental resins ensures safety and reliability, particularly for intraoral devices and components that come in direct contact with patients.

5. Cost

While initial investment is a consideration, cost-effectiveness also depends on a printer’s efficiency, resin costs, and reliability. Budget-friendly printers like the DJ89 PLUS offer high-resolution LCD printing at an affordable price, making advanced 3D printing accessible to more dental practices and labs.

Applications of Dental 3D Printing

3D printing is transforming the range of services offered in dentistry by enabling quick, precise, and custom-made dental solutions. Here are some of the most popular applications:

Orthodontic Models

3D printers allow orthodontists to produce accurate models of patients’ teeth for treatment planning and device fabrication. 3D printed orthodontic models streamline the process, reducing the time required for creating dental molds.

Restorative Models

Restorative models are used to design crowns, bridges, and other prosthetics, ensuring a precise fit before production. With 3D printing, dental professionals can create highly detailed models that reflect the patient’s exact dental anatomy, aiding in the customization and accuracy of prosthetics.

Surgical Guides

Surgical guides are crucial for implant placement, as they guide the surgeon’s drill to ensure proper alignment and positioning. 3D printed guides can be customized for each patient and produced at a fraction of the cost of traditional methods, improving both precision and patient outcomes.

Temporary Restorations

Temporary restorations allow patients to maintain dental function and aesthetics while waiting for permanent solutions. With 3D printing, temporary crowns, bridges, and veneers can be created quickly, ensuring patients experience minimal disruption during treatment.

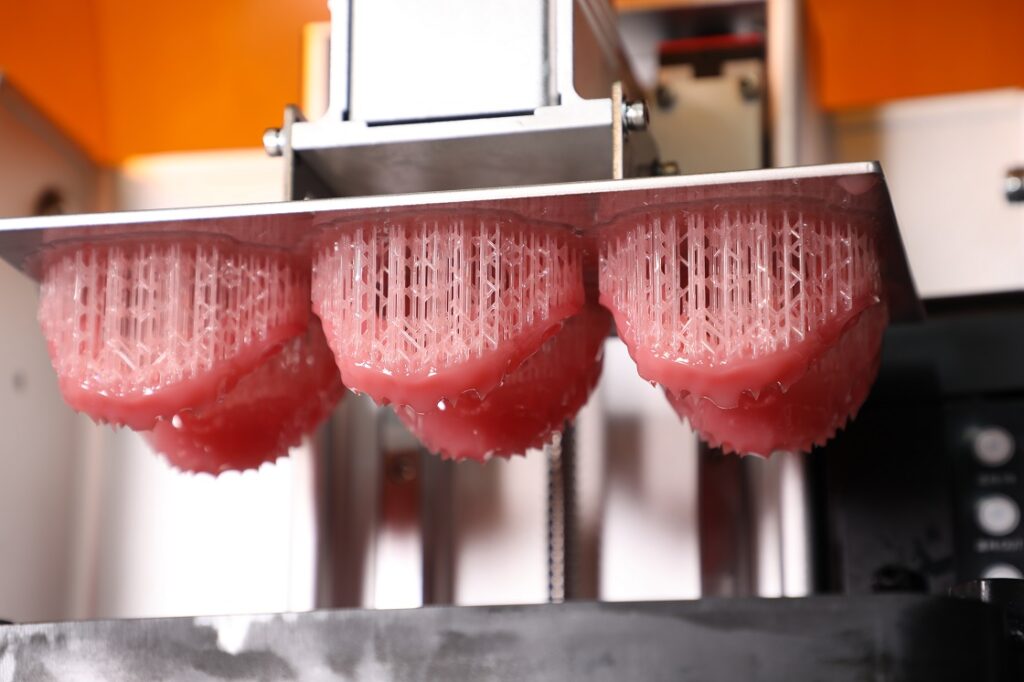

Full Dentures and Try-Ins

3D printing enables the production of full dentures and try-in models, allowing patients to try on their dentures for fit and appearance before the final product is made. This reduces the number of adjustments required and ensures a more accurate, comfortable fit.

Piocreat’s 3D Printers for Dentistry

Piocreat offers several high-quality 3D printers designed specifically for dental applications, each with unique features tailored to different needs in dental labs and clinics.

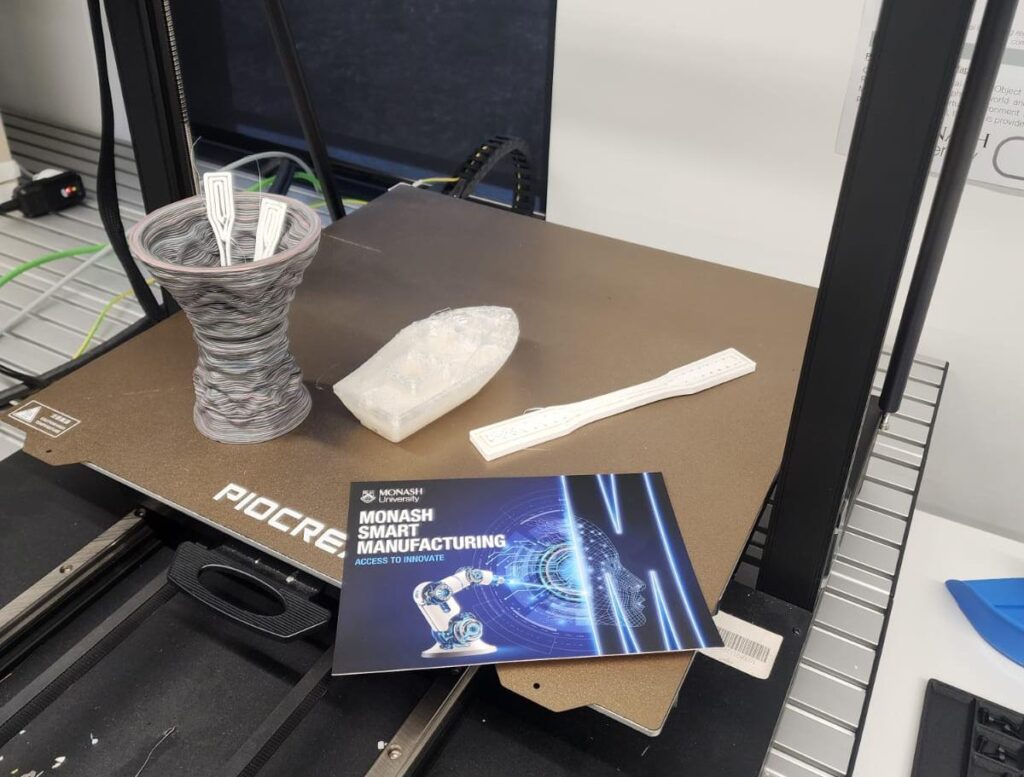

DJ89 PLUS: Cost-Effective LCD 3D Printer for Dentistry

The DJ89 PLUS is an 8K 10.3″ LCD 3D printer that is highly cost-effective for both dental and jewelry applications. Its high resolution makes it ideal for creating intricate dental models and prosthetics with superior clarity and detail.

Key Features of the DJ89 PLUS:

- 29μm Pixel Size: This ultra-high resolution enables the production of extremely detailed models, essential for precise fittings.

- Heating Chamber: Maintains optimal resin temperature, reducing printing inconsistencies and improving overall quality.

- Automatic Feeding: Streamlines the printing process, reducing the need for manual intervention.

- Stable Z-axis Structure: Ensures high stability and accuracy throughout the print, critical for dental models.

The DJ89 PLUS is an affordable option that doesn’t compromise on detail, making it a great choice for practices and labs that prioritize quality without a high initial investment.

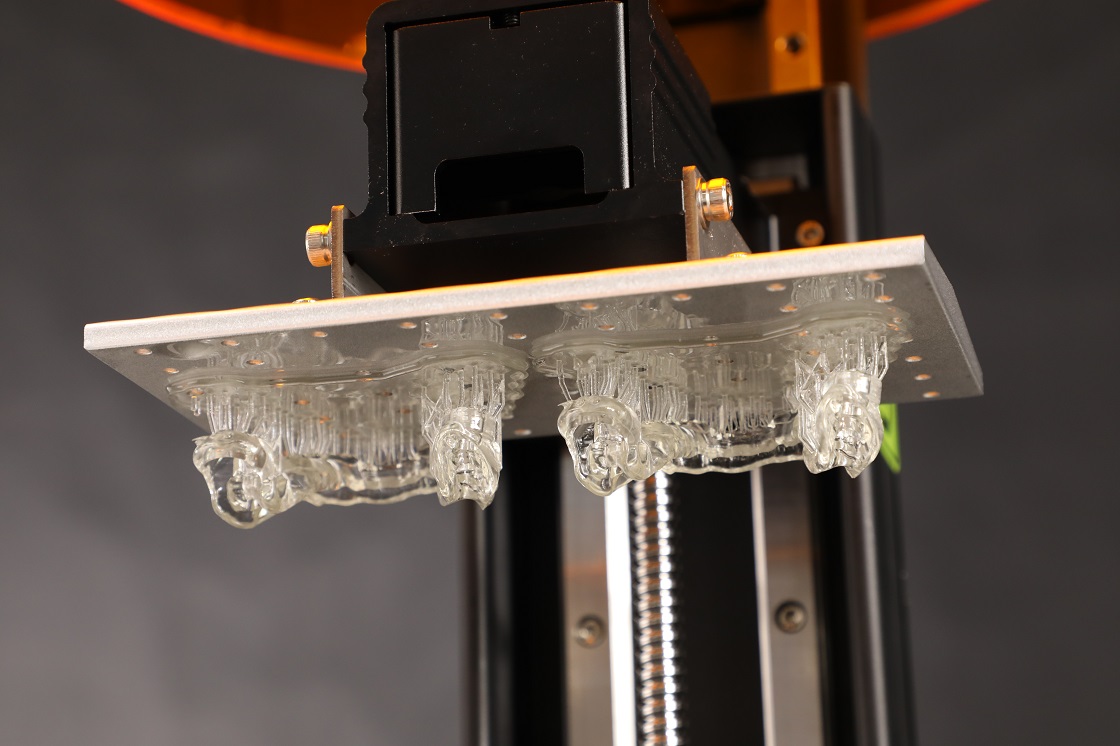

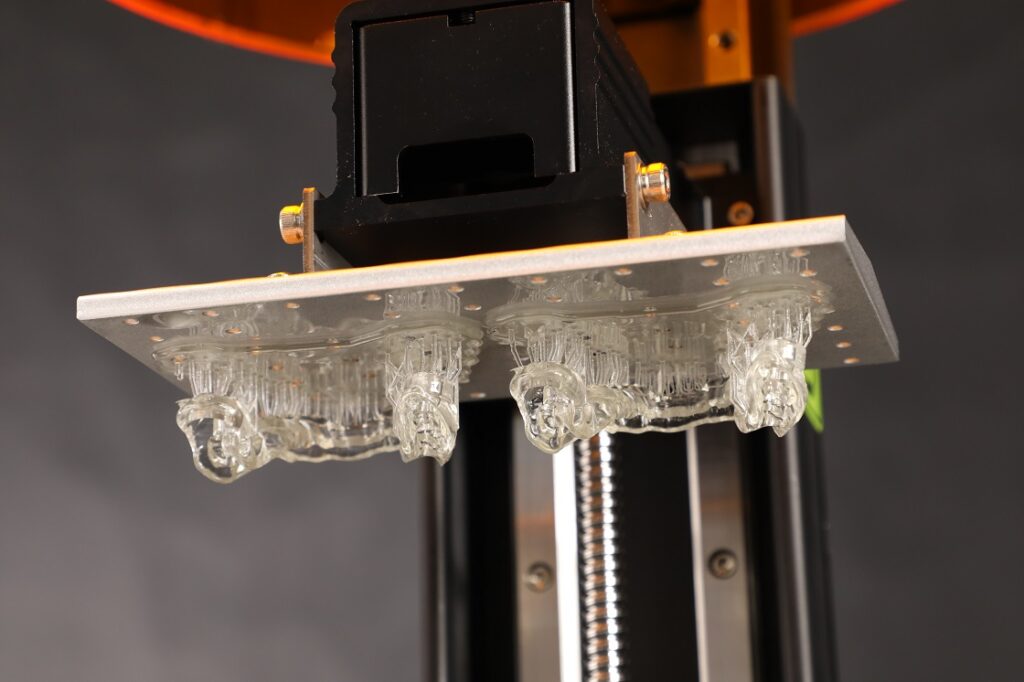

D158: Compact DLP 3D Printer with Texas Instruments Technology

The D158 is a compact DLP 3D printer specifically designed for dental applications, equipped with Texas Instruments technology for enhanced accuracy. This printer is reliable and straightforward, with several advanced features that make it suitable for dental labs and orthodontic practices.

Key Features of the D158:

- Automatic Lifting Cover: Simplifies operation and protects prints from dust or environmental variables.

- 62μm Pixel Size: Offers high detail for complex dental models, ensuring the accuracy required for prosthetic and orthodontic applications.

- High-Speed Release Film: Allows for faster prints without compromising quality.

- Stable Z-axis Structure: Ensures consistent accuracy for parts that require precision.

The D158 is an excellent option for dental professionals who need reliable, high-quality output in a compact design, making it perfect for both small labs and larger practices.

D150: Fastest DLP 3D Printer for High Productivity

The D150 is designed for high productivity, boasting speeds of up to 80mm/h. With its adjustable light intensity (6000-20000 uw/cm2), this printer delivers quick, high-quality results, ideal for professionals with demanding schedules and high output requirements.

Key Features of the D150:

- Speeds up to 80mm/h: Provides unmatched productivity, enabling quick turnarounds for dental labs with heavy workloads.

- High-Speed Release Film: Allows for smooth layer release, reducing the time needed for each print.

- Adjustable Light Intensity: Offers customization based on the specific resin or model requirements, improving print quality and consistency.

- Light Engine Life 30,000+ Hours: Ensures long-lasting performance, reducing maintenance needs and cost over time.

The D150 is the go-to choice for busy dental labs that need fast, reliable output for high-volume production.

Conclusion

3D printing technology is revolutionizing the dental industry, making it easier than ever to create custom models, surgical guides, and restorations quickly and affordably. When choosing a dental 3D printer, it’s essential to consider factors like print speed, ease of use, accuracy, material options, and cost to ensure the device meets the specific needs of your practice or lab.

Piocreat’s DJ89 PLUS, D158, and D150 models each bring unique benefits to dental applications, from cost-effective high-resolution prints to high-speed, high-output capabilities. By investing in the right 3D printer, dental professionals can enhance their workflow, improve patient satisfaction, and provide more accurate, tailored care in a fraction of the time.

Whether you’re looking to increase productivity or elevate the quality of your dental services, these 3D printers from Piocreat offer the reliability and performance needed to succeed in modern dentistry.