Exquisite Dragon Carving Printed with PioCreat G12: A Case Study in FGF 3D Printing

piocreat3d

on

September 16, 2024

The PioCreat G12 Fused Granulate Fabrication (FGF) pellet 3D printer has made a significant impact across various industries by offering an efficient and versatile solution for large-scale additive manufacturing. With its ability to handle high-speed thermoplastic extrusion and a sizable build volume, this printer is particularly suited for creating intricate designs, patterns, molds, tooling, and prototypes. In this post, we’ll explore a stunning example of what the PioCreat G12 can accomplish: an exquisite dragon carving. This project showcases the power of FGF technology and highlights the benefits it offers for both beginners and experts alike.

Understanding Fused Granulate Fabrication (FGF) 3D Printing

Fused Granulate Fabrication (FGF) is an advanced form of 3D printing that uses plastic pellets instead of traditional filament or resin. FGF technology, such as that used in the PioCreat G12, is ideal for large-format printing projects due to its high throughput and cost-efficiency.

Unlike filament-based 3D printers, FGF machines like the G12 can process granules of thermoplastic materials at a much faster rate, making them perfect for large objects or batch production. This makes it popular in sectors such as manufacturing, automotive, aerospace, art, and architecture, where creating large, custom objects quickly and cost-effectively is essential.

Key features of the PioCreat G12 include:

- Build volume: 1200×1000×1000mm, making it one of the largest 3D printers available for producing massive designs.

- High-speed extrusion: Allows for faster production times while maintaining high precision.

- Thermoplastic material options: The ability to work with a wide range of thermoplastic materials, including reinforced compounds that enhance strength and durability.

The G12’s FGF printing process brings together speed, versatility, and precision, ensuring the best results for any large-scale project. To better illustrate these capabilities, let’s dive into a recent case study involving a detailed dragon carving.

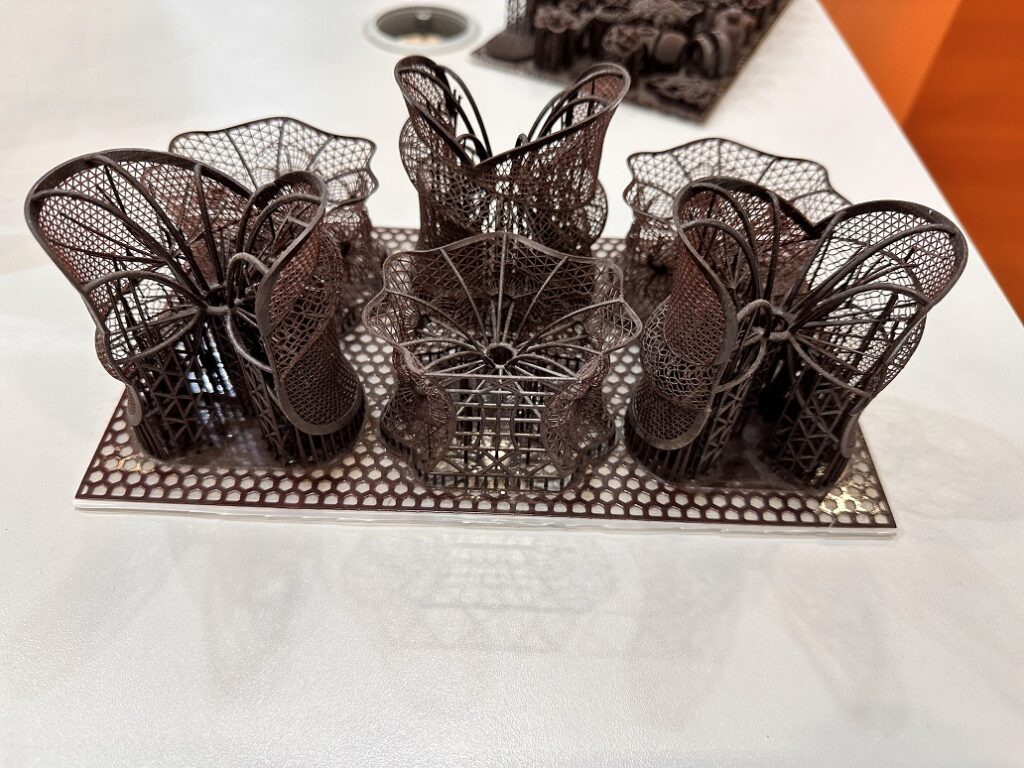

Case Study: The Exquisite Dragon Carving

One of the most impressive demonstrations of the PioCreat G12’s capabilities is the creation of an intricate dragon carving. This detailed, large-scale sculpture showcases the high level of customization and precision that can be achieved with FGF technology. Designed for use as both an indoor and outdoor decorative element, the dragon carving can be mounted on walls or hung as a striking art piece.

Project Specifications

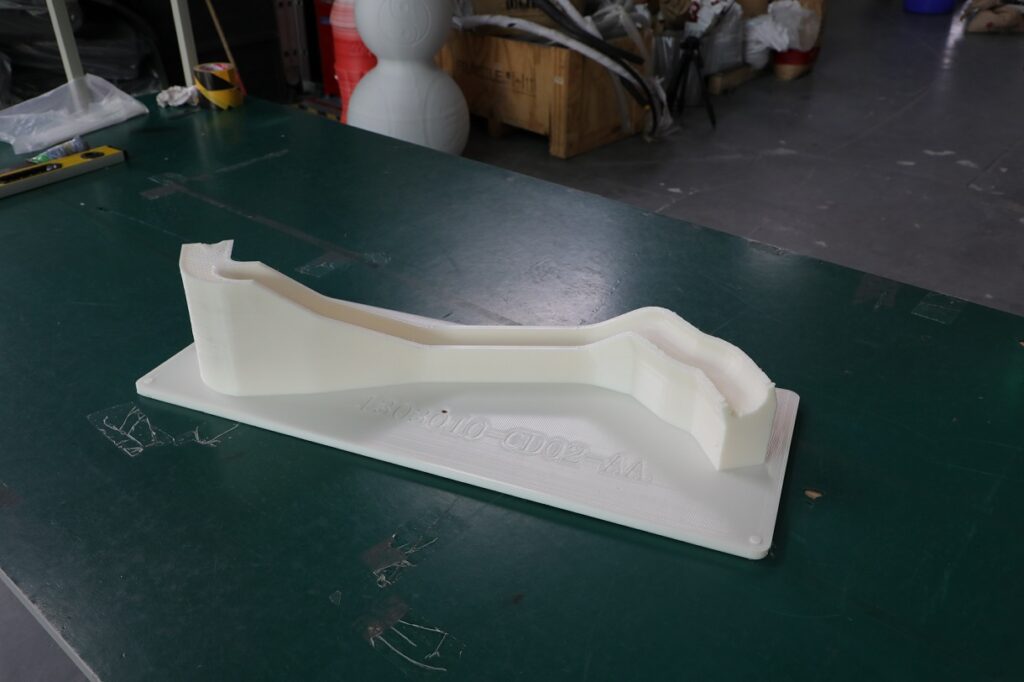

For this project, the PioCreat G12 printed the dragon carving using PETG mixed with 30% glass fiber reinforcement. This material choice was essential for several reasons:

- Weather resistance: PETG offers excellent durability, making it suitable for outdoor use in various environmental conditions.

- Mechanical properties: The 30% glass fiber reinforcement provides additional strength, which is critical for sculptural applications where rigidity and stability are important.

- Sculptural detail: PETG’s flexibility ensures that even the smallest details in the dragon’s design are accurately rendered.

Production Process and Results

The PioCreat G12’s ability to handle large-scale, intricate designs is reflected in the dimensions and complexity of the dragon carving. With a model size of 750x750x50mm, the design required precise layering to capture the intricate scales, facial features, and flowing lines of the dragon. Despite its size, the G12’s 0.8mm nozzle allowed for detailed work, while the 1mm line width ensured that the overall form was strong enough to endure both indoor and outdoor environments.

One of the key benefits of using FGF technology for this project was the speed of production. The dragon carving was completed in 65 hours, a remarkable turnaround for a model of this size and complexity. Traditional methods of sculpting or manufacturing such a piece could take weeks or months, but with the G12’s high-speed extrusion, production times are dramatically reduced.

Moreover, the infill density of 15% was carefully chosen to balance strength and material efficiency. This density provided enough internal support to maintain structural integrity while keeping material use and weight to a minimum.

Versatility of the Finished Product

Once printed, the dragon carving offers a wide range of applications:

- Indoor decoration: The carving’s fine detail and elegant design make it a perfect addition to an interior space, either as a centerpiece or a wall-mounted art piece.

- Outdoor installation: Thanks to the weather-resistant PETG material, the dragon carving can be used as a durable outdoor decoration. Whether mounted on a wall in a garden or displayed in a public space, the carving is built to withstand the elements without losing its intricate detailing.

The flexibility of the PioCreat G12 in terms of material and design makes it an excellent choice for projects that need to combine aesthetic appeal with functional durability.

The Advantages of PioCreat G12 for Large-Scale Projects

The PioCreat G12 FGF 3D printer excels in several key areas that make it an ideal tool for large-scale printing projects like the dragon carving:

- Lower production costs: By using thermoplastic pellets instead of filament, the PioCreat G12 reduces material costs, especially when working with high-volume projects.

- Faster turnaround times: Thanks to its high-speed extrusion process, the G12 can significantly reduce the production time for large-scale models and prototypes. This makes it a valuable asset for industries that require quick iterations and rapid prototyping.

- Unmatched customization flexibility: Whether printing an intricate sculpture or a functional part, the PioCreat G12 offers unparalleled control over design and customization. The ability to fine-tune settings such as nozzle size, layer thickness, and infill density means that users can tailor each project to specific requirements.

Conclusion: The Future of Large-Scale 3D Printing

The exquisite dragon carving produced by the PioCreat G12 demonstrates the transformative potential of FGF 3D printing technology. With its ability to handle complex, large-scale projects, the G12 offers an innovative solution for industries ranging from architecture and art to aerospace and manufacturing. Whether you’re a beginner exploring the possibilities of 3D printing or an expert looking to push the boundaries of additive manufacturing, the PioCreat G12 delivers precision, speed, and versatility.

As 3D printing continues to evolve, the capabilities of machines like the G12 will only expand, paving the way for even more ambitious and creative projects across various industries. For anyone seeking to create large-scale, custom designs, the PioCreat G12 is a powerful tool that unlocks new possibilities in additive manufacturing.