How to Achieve High-Quality Prints with Pellet 3D Printers

piocreat3d on June 16, 2025

Table of Contents

Pellet Material Testing

Purpose: Adjust nozzle temperature and flow rate for current ambient conditions to achieve better printing results

A. Determining Optimal Nozzle Temperature

- Set Initial Temperature

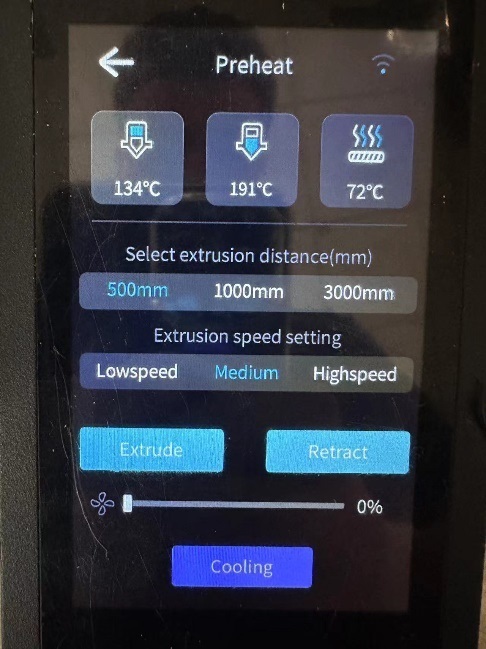

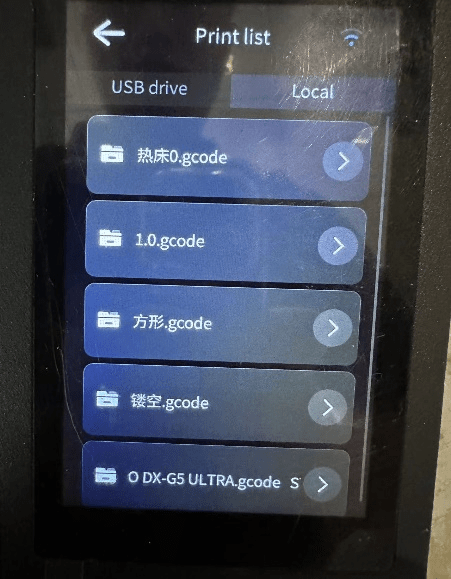

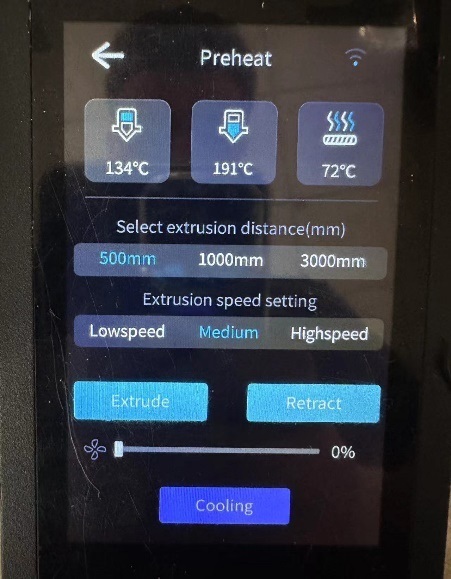

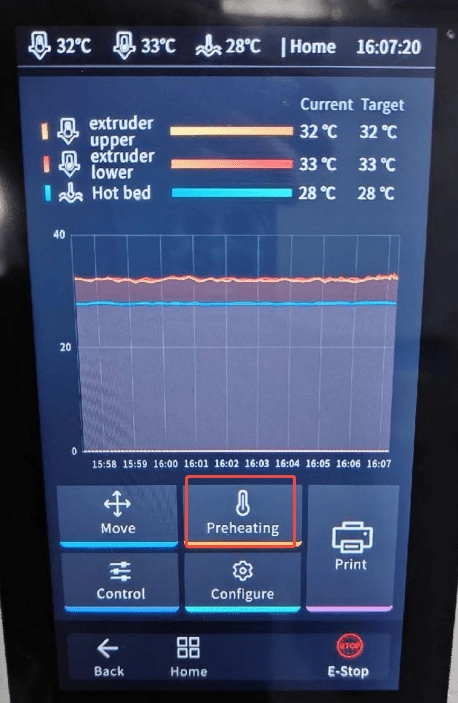

- Navigate to ‘Preheating’ Settings on the display.

- Input the recommended temperatures for Hotend upper and hotend lower

pellets | Hotend upper | hotend lower |

ABS | 160 | 190 |

PLA | 170 | 210 |

PETG-1211 | 180 | 220 |

PETG | 200 | 230 |

TPU(1.2 1.5 nozzle) | 160 | 190 |

TPU(2.0 3.0 4.0 nozzle) | 170 | 200 |

- Extrude Material

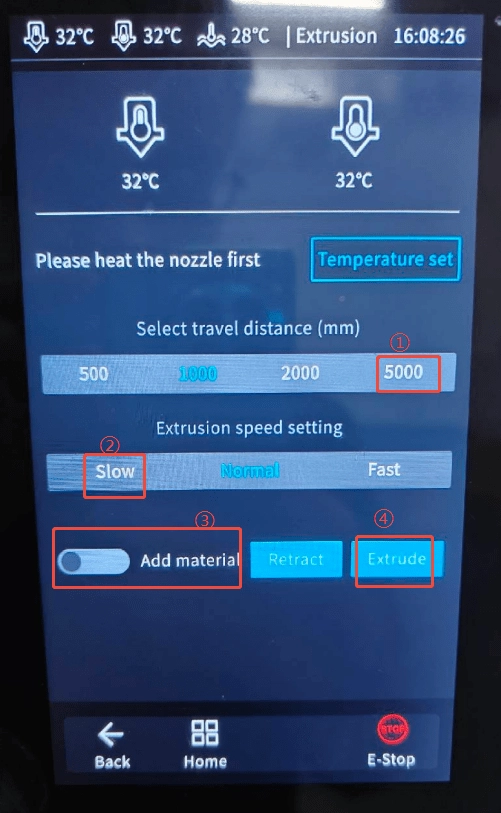

- After reaching target temps, set the ‘distance’ to ‘5000mm’, and the ‘speed setting’ to ‘Slow’.

- If the feed tube is empty: Click “Load Material”.

- Then select “Extrude”.

- Evaluate Extrusion Quality

- Ideal Output:

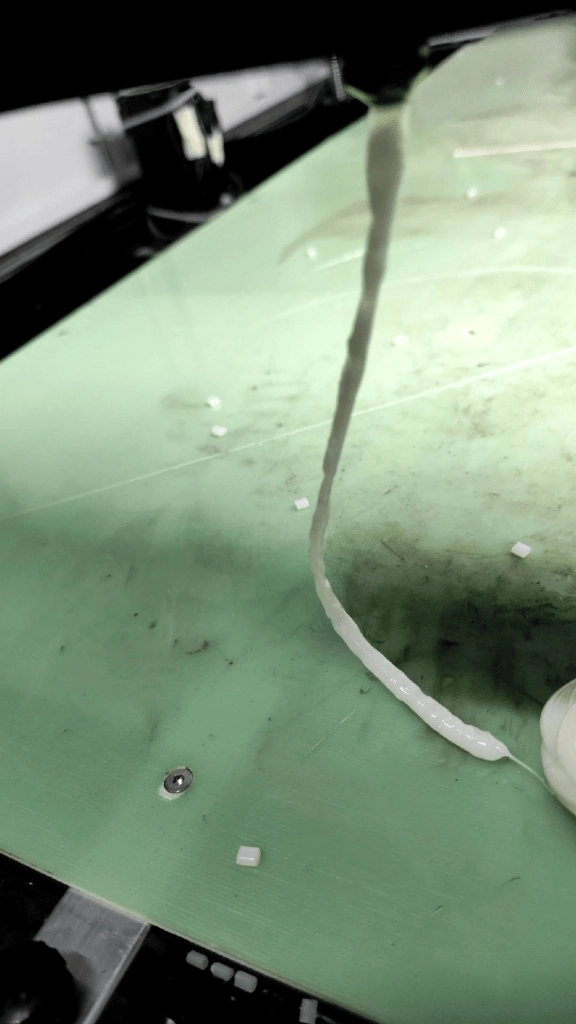

- Smooth, continuous flow without breaks/unmelted particles.

- Strong tackiness between layers.

- Minimal oozing when idle.

- Temperature Adjustment

- Too High: Excess oozing, rough surface texture → Lower by 5–10°C.

- Too Low: Grinding noise from extruder, weak layer adhesion → Increase by 5–10°C.

- Check for Moisture

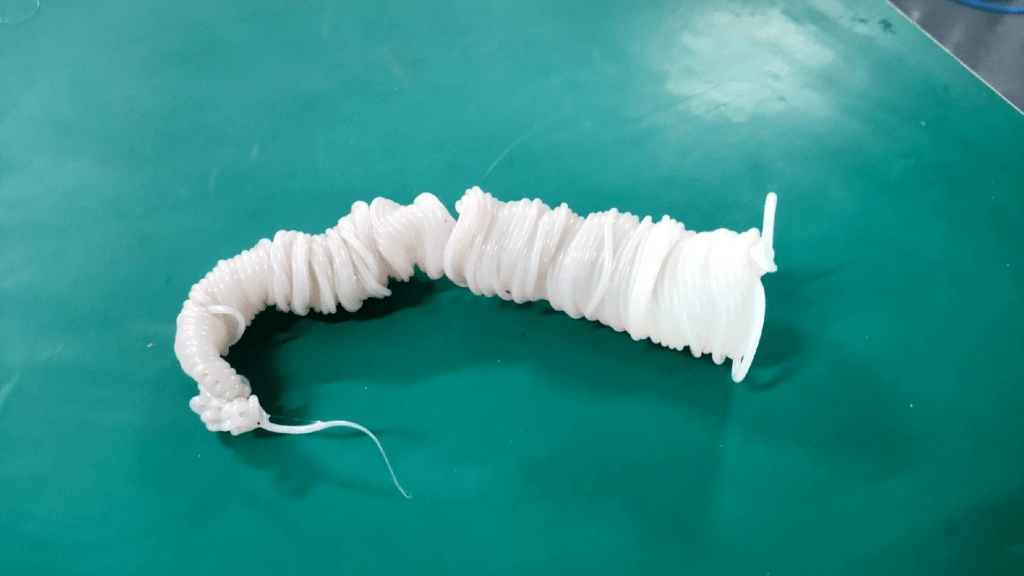

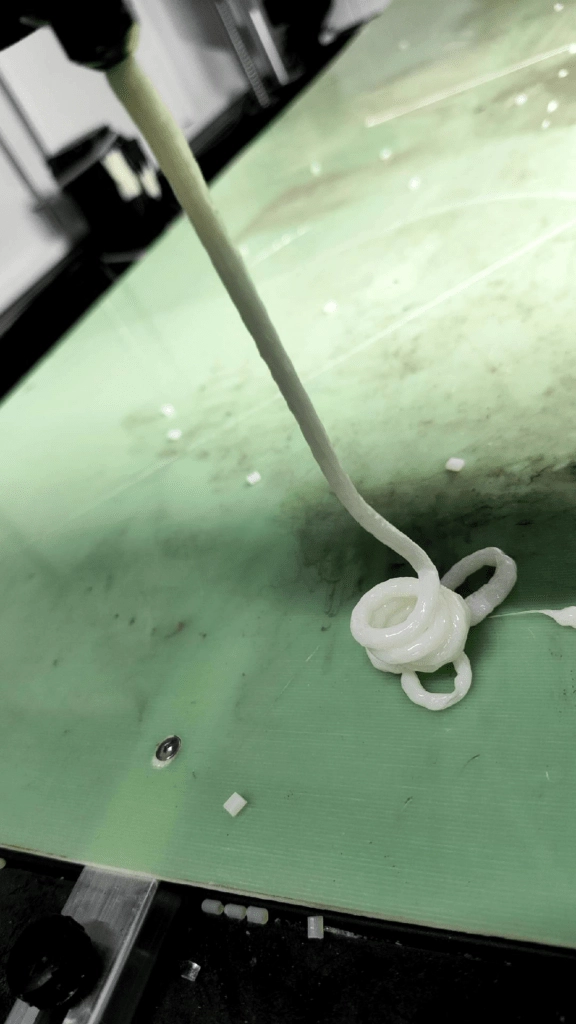

- Signs of Wet Filament: Popping/crackling sounds during extrusion.

- Bubbles inside extruded strands.

- Solution: Dry filament (or reduce temp as a temporary fix).

- Image: Wet filament exhibits foamy, porous strands.

| Common material drying parameters | ||

| pellets | Temp (°C) | Time (h) |

| PLA | 50 | 1 to 3 |

| PETG | 60-70 | 2 to 4 |

| ABS | 80 | 2 |

| TPU | 95-110 | 2 to 4 |

Others pellet | Temp(°C) | Time (h) |

ABS | 80 | 3 |

PC | 120 | 3 |

PC/ABS | 100 | 3 |

PA6 | 80 | 3 |

PA66 | 80 | 3 |

PA66GF35% | 80 | 3 |

PMMA | 80 | 3 |

POM | 100 | 3 |

PBT | 120 | 3 |

PPO | 100 | 3 |

PPS | 150 | 3 |

PET | 125 | 3 |

PPE | 100 | 3 |

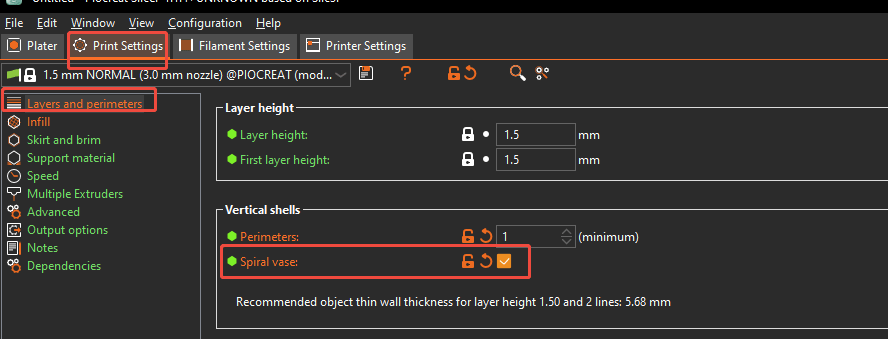

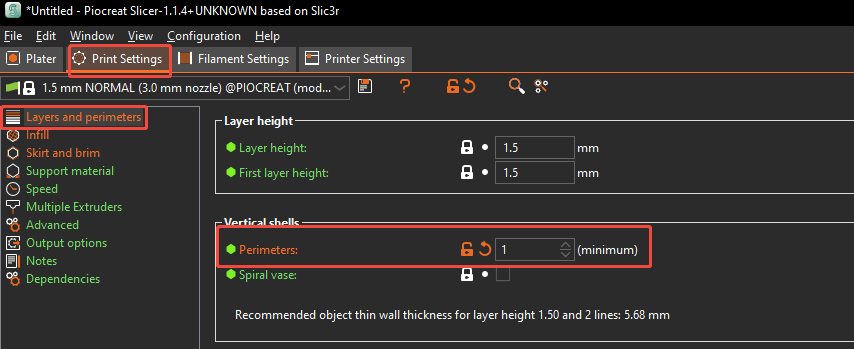

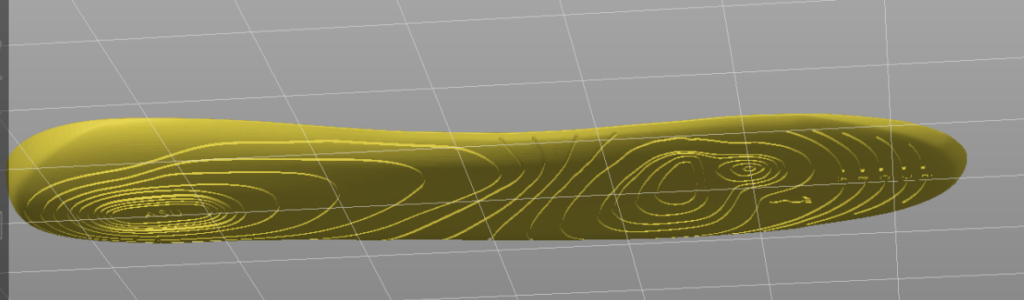

- Validation Print

- Print a hollow cube/cylinder in “Spiral vase”.

- Use pliers to bend the model 90° — if it doesn’t crack, the temperature is optimized.

B. Flow Rate Calibration

Reference Video: Start at 0:43.

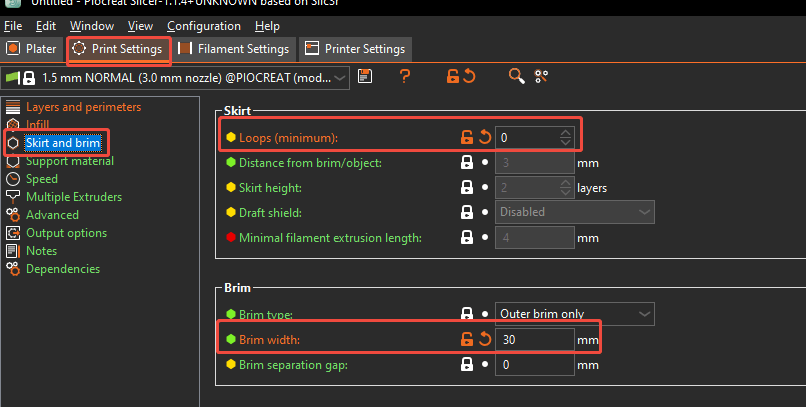

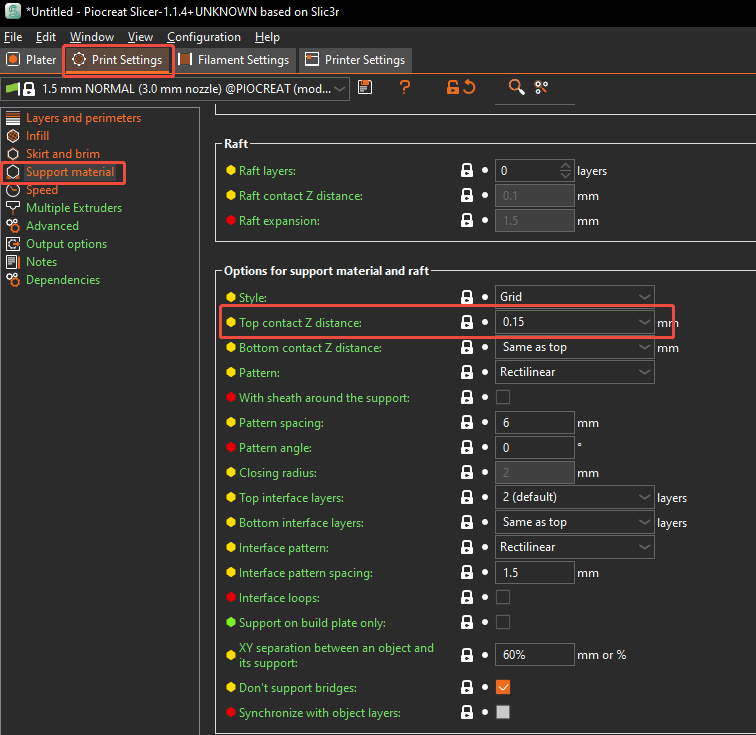

Slicing Software Techniques

A. Nozzle Selection Guidelines

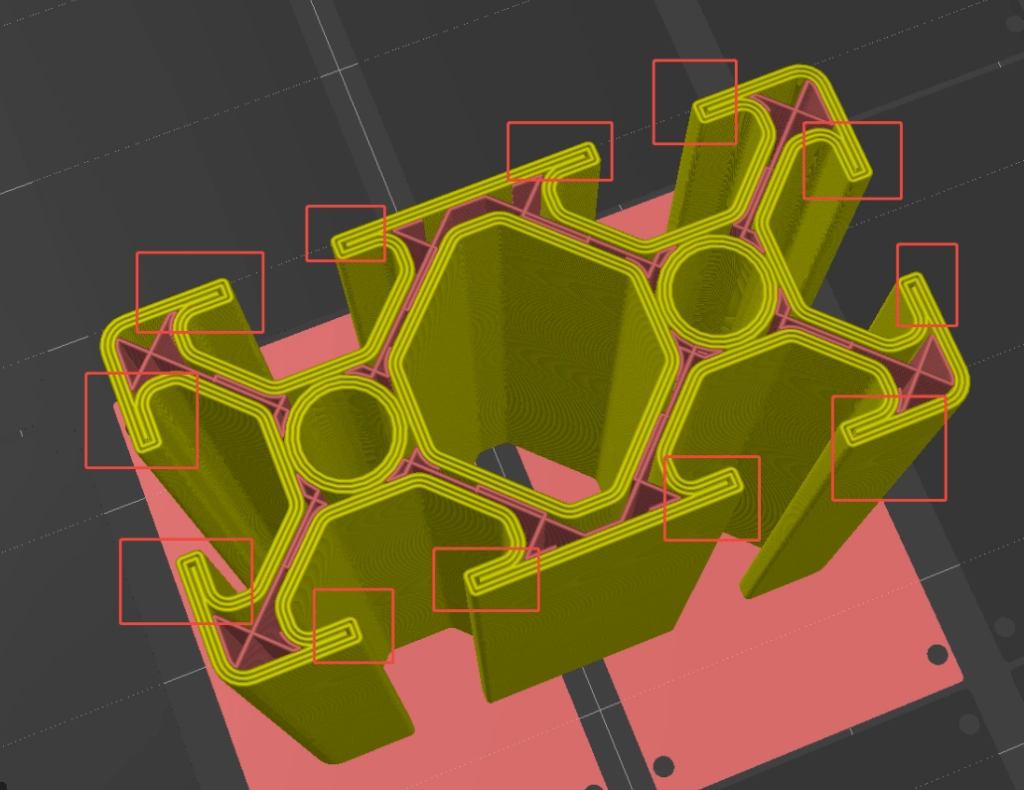

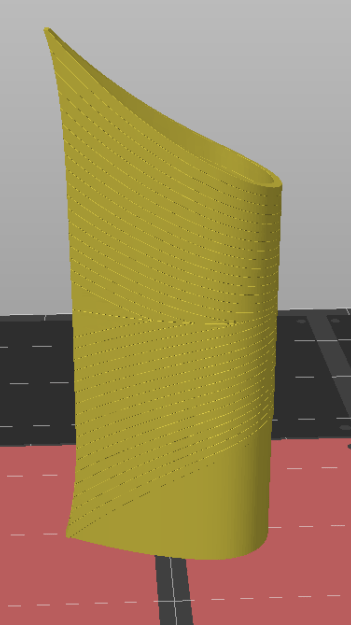

- Thin-Walled Models

- Problem: Small wall thickness can cause over-extrusion at corners, leading to layer defects or nozzle collisions.

- Solutions:

- Use a smaller nozzle diameter (e.g., 2mm instead of 3mm).

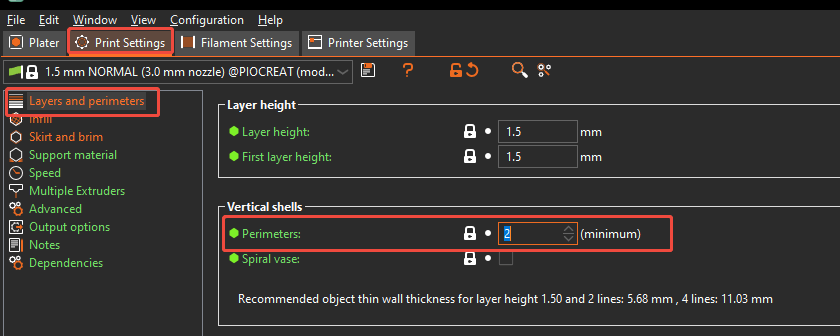

- Reduce ‘Perimeters’ to reduce wall layers:

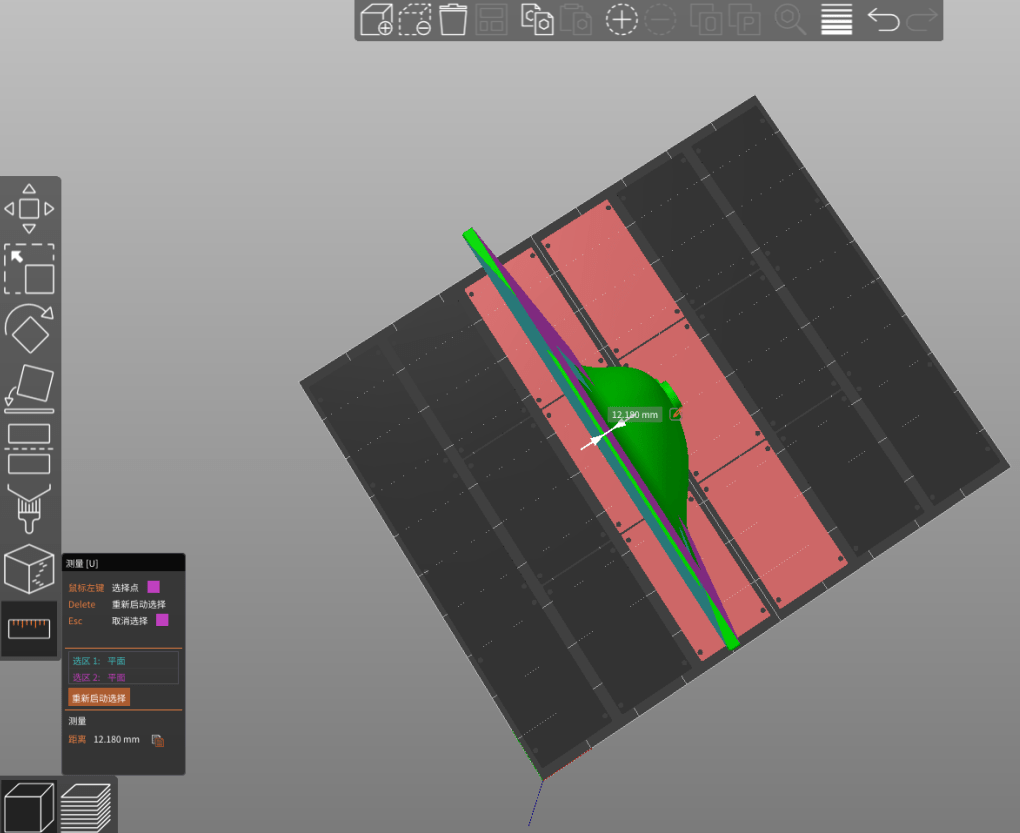

- Example: For a 12mm thickness shell, use:

- 2mm nozzle → 2 wall layers

- 3mm nozzle → 1 wall layer (to prevent excess material buildup).

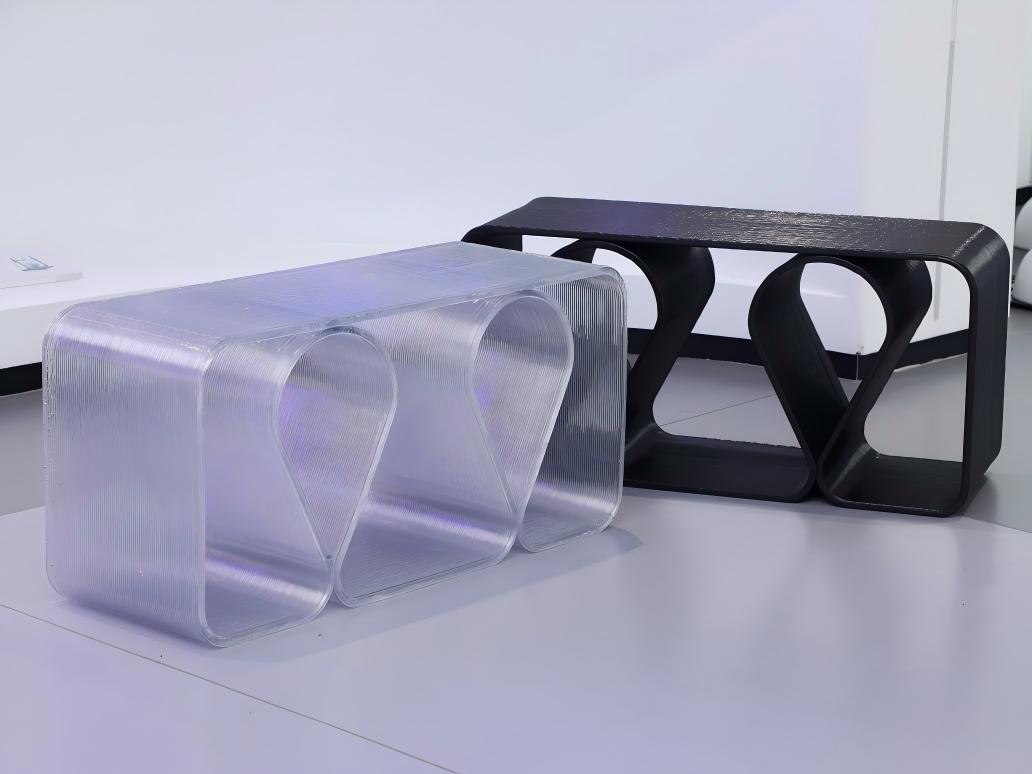

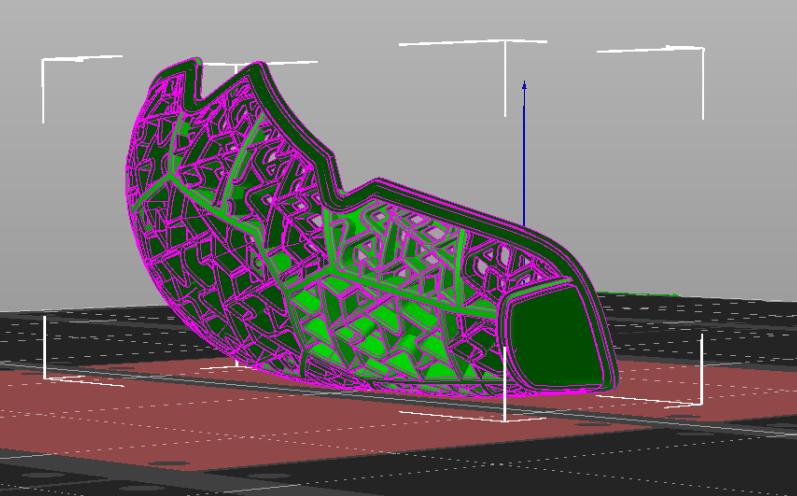

- Visual Comparison:

- Left:2mm nozzle (double extrusion at corners → bulging).

- Right:5mm nozzle (smooth transitions).

- Holes Near Edges

- Causes: Tight spacing leads to material buildup.

- Solutions:

- Reduce ‘Perimeters’ to 2.

- Switch to a smaller nozzle.

- Redesign model to increase hole-edge distance.

B. Special Model Optimization

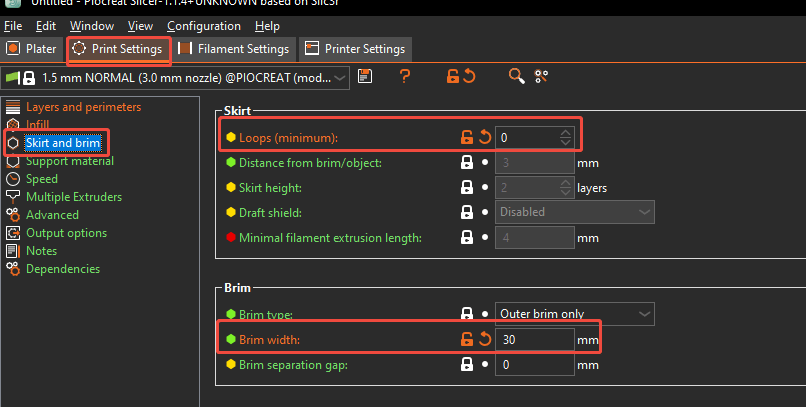

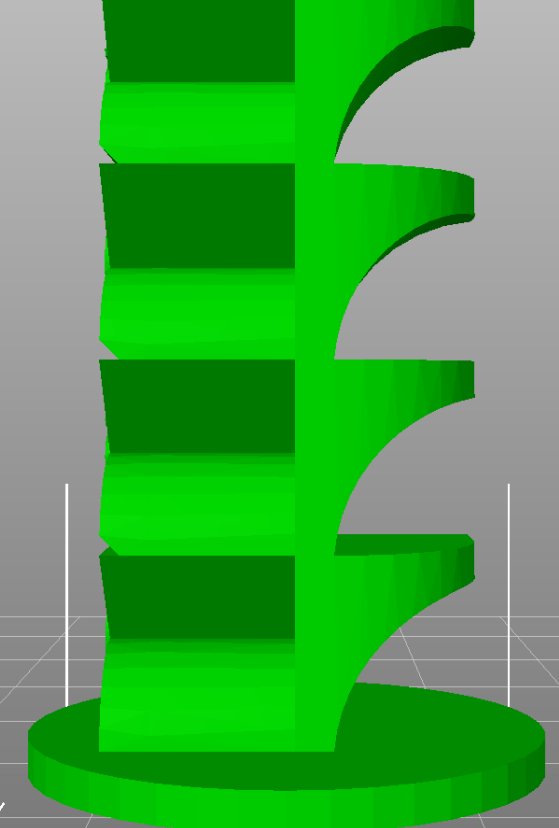

- Small Footprint + Tall Models

- Risk: Bed adhesion failure at higher layers.

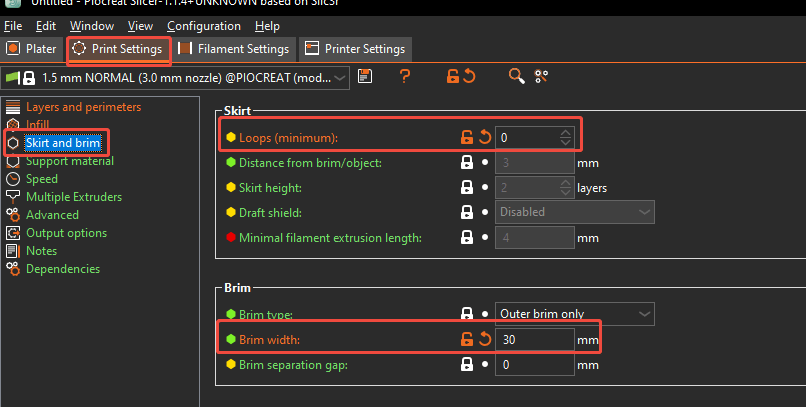

- Fix: Apply glue stick or use a wide brim (10 times the nozzle diameter).

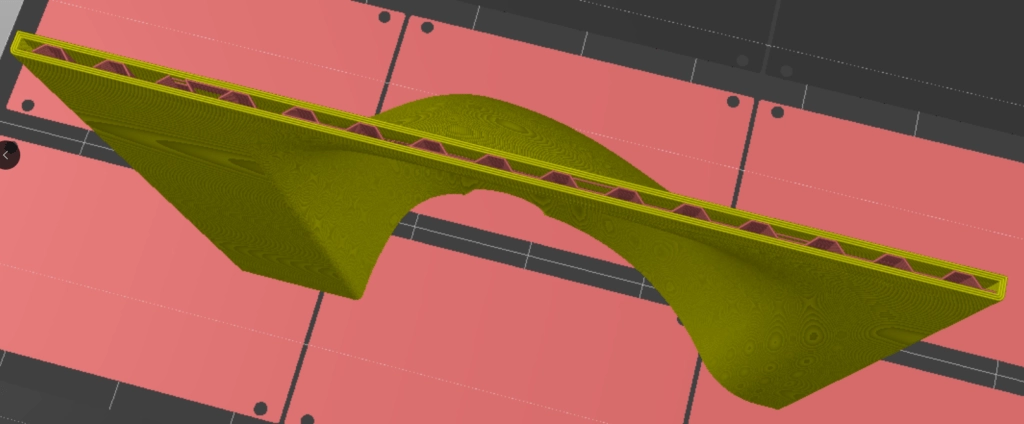

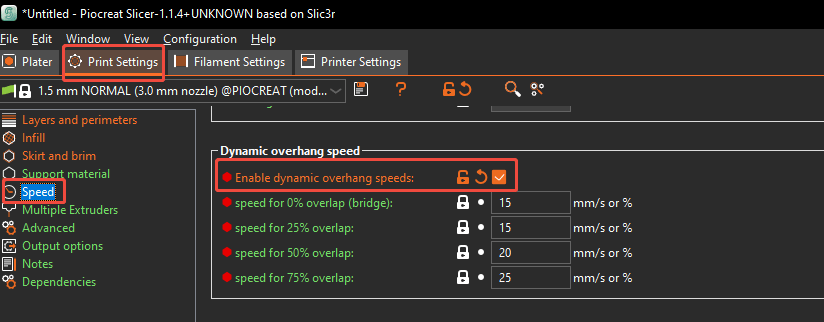

- Steep Overhangs (Drooping)

- Partial Solutions:

- Enable dynamic overhang speeds

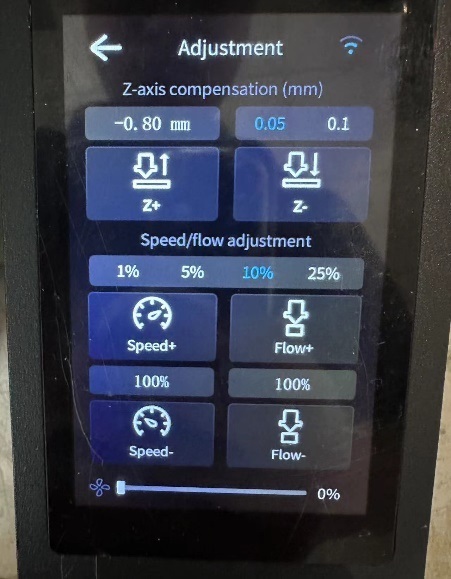

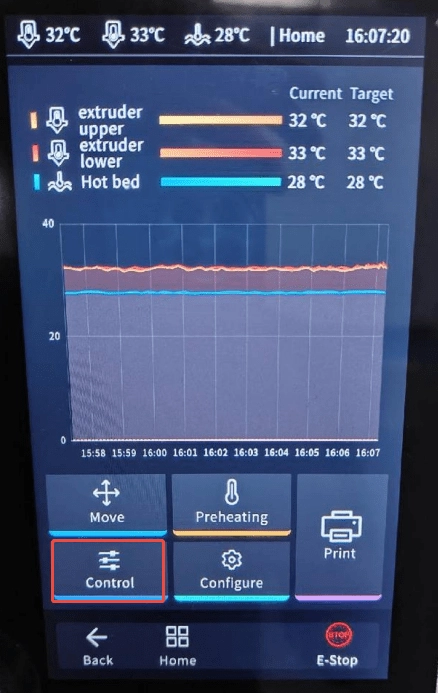

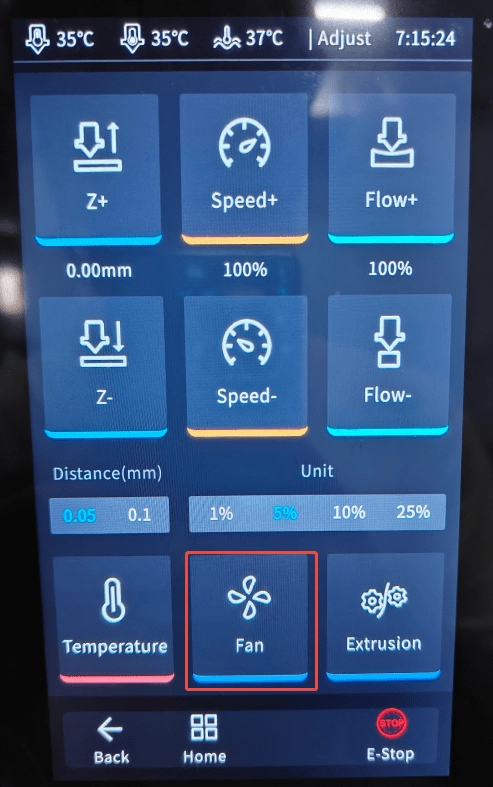

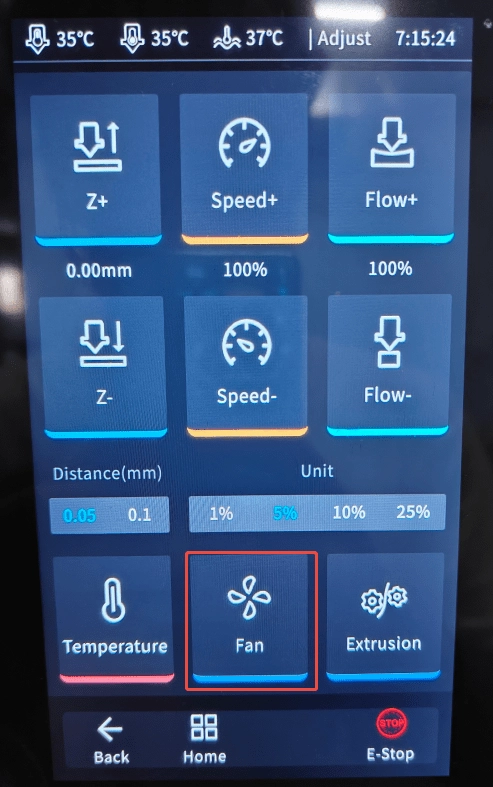

- Increase cooling fan speed (navigate to: ‘Adjuct’> ‘Fan’ during print).

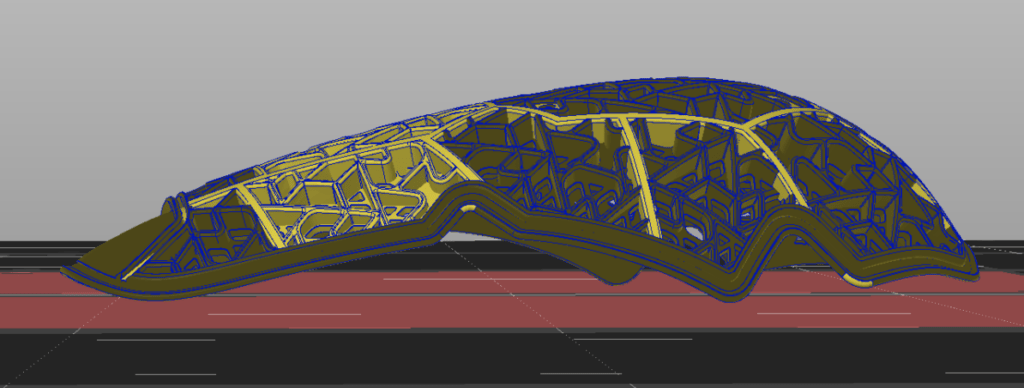

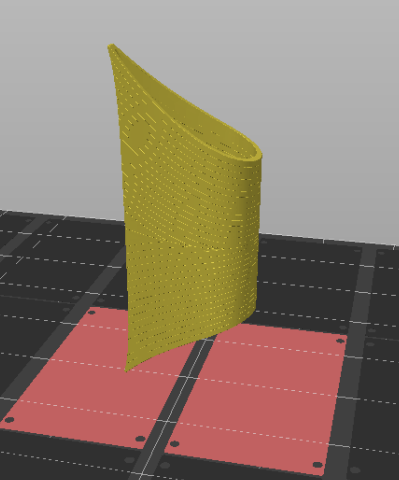

- Model Orientation

- Poor (Left):Requires excessive supports, prone to dropping.

- Better (Right):Optimized angle reduces supports and improves quality.

- Top-Heavy Models

- Stabilize with: Glue or a large brim.

- Hard-to-Remove Supports

- Adjust support Z-distance (increase gap between support and model).

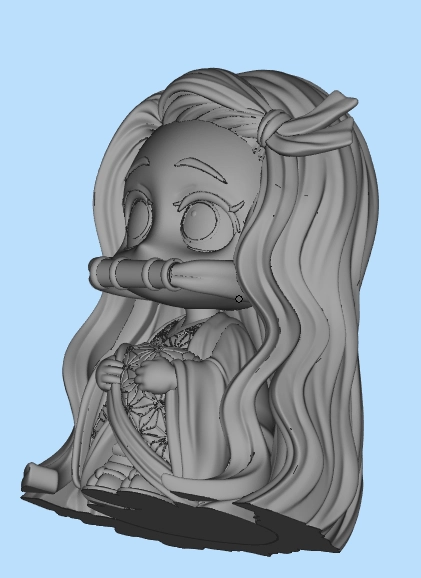

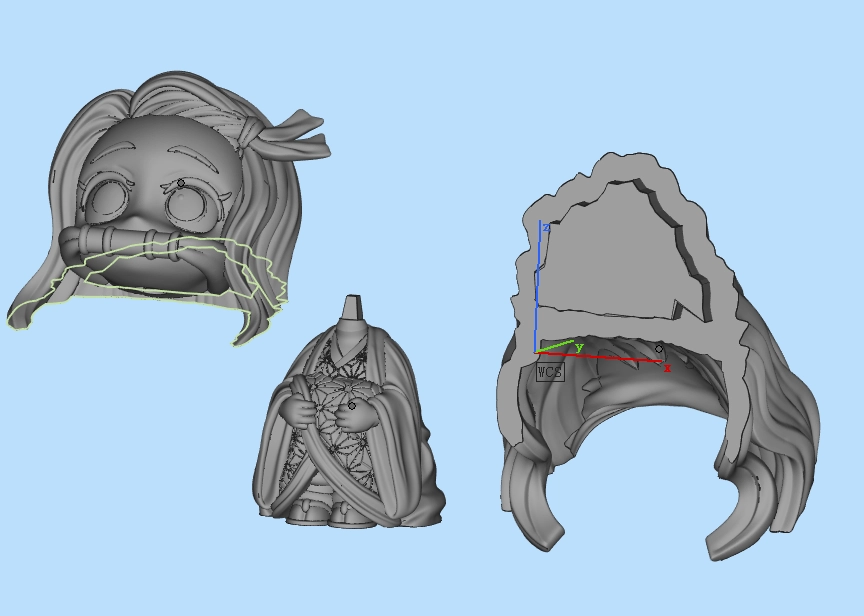

C. Design Adjustments for Printability

- Models with Minimal Bed Contact

- Redesign: Add a removable base for stability (avoids messy supports).

- Large, Support-Heavy Models

- Split into parts, print separately, and assemble post-printing.

- Irregular Bottom Surfaces

- Reposition vertically + add a custom support base + large brim.

Troubleshooting Common Print Failures

- Layer Separation

Causes & Solutions:

- Material Runout: Check if the filament spool is empty or jammed.

- Sensor Issues: Ensure the filament sensor isn’t stuck due to static electricity.

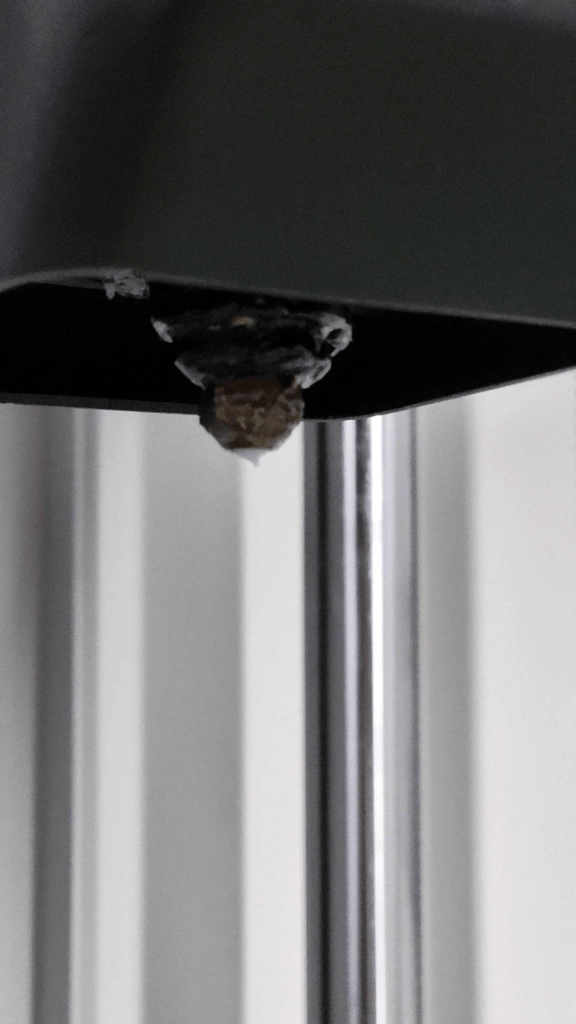

- Overheating: If the upper nozzle cools too slowly, the filament may gum up.

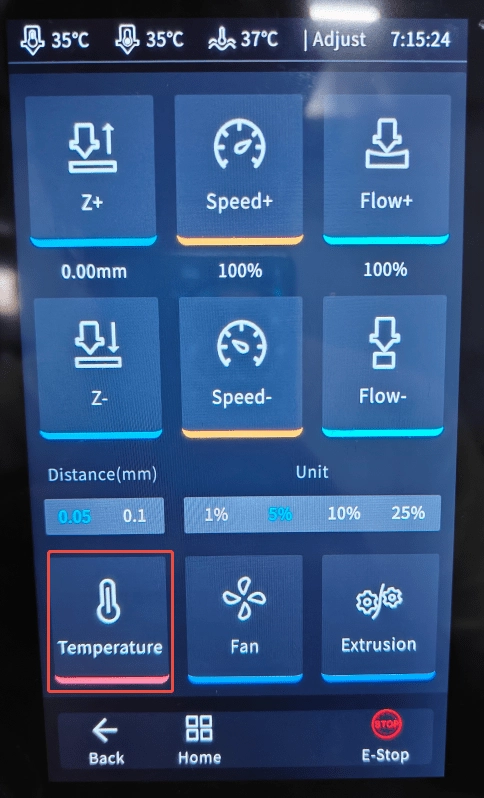

- Fix:Reduce upper nozzle temp by 5–10°C(navigate to: ‘Adjuct’ > ‘Temperature’ during print).

- Over-Extrusion

Solutions:

- Material-Specific Settings:

- TPU/Soft Filaments:Disabled retraction (causes clogs). Minor over-extrusion is normal for pellet printers.

- Retraction settings:

- Use slicer’s default retraction settings for Piocreat pellets brand.

- Overheating:

- Fix:Reduce upper nozzle temp by 5–10°C(navigate to: ‘Adjuct’ > ‘Temperature’ during print).

- Flow Rate Check:

- Ensure flow calibration isn’t set too high.

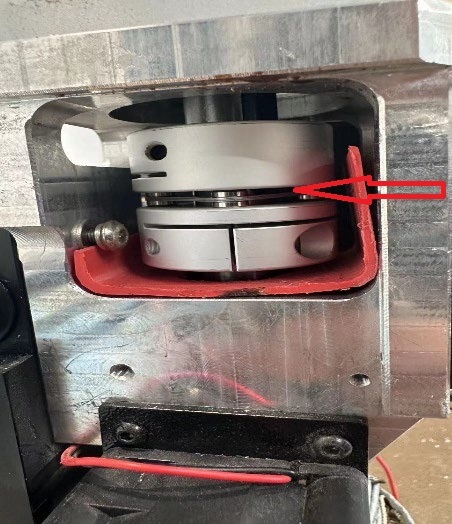

- Nozzle Wear:

- Replace if the orifice is wider than slicer settings (e.g., 0.4mm nozzle worn to 0.5mm).

- Poor Layer Adhesion

Fixes:

- Increase Nozzle/Bed Temp:

- Raise by 5–15°C(navigate to: ‘Adjuct’> ‘Temperature’ during print).

- Drafts/Temperature Swings:

- Avoid AC/fans blowing directly on the printer.

- Diagonal Patterns/Wobble

Root Causes:

- Tall Model Instability:

- Add a large brim.

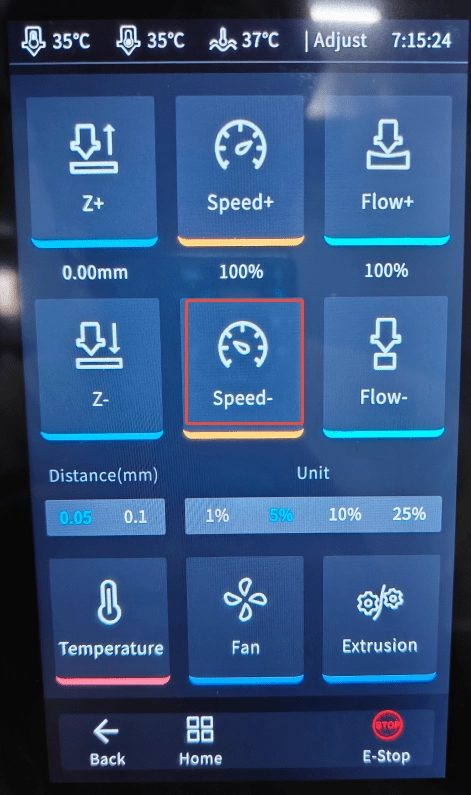

- Reduce print speed by 20–30%(navigate to: ‘Adjuct’> ‘Speed-‘ during print).

- Uneven Cooling:

- Ensure cooling fans evenly cover the model (avoid partial airflow).

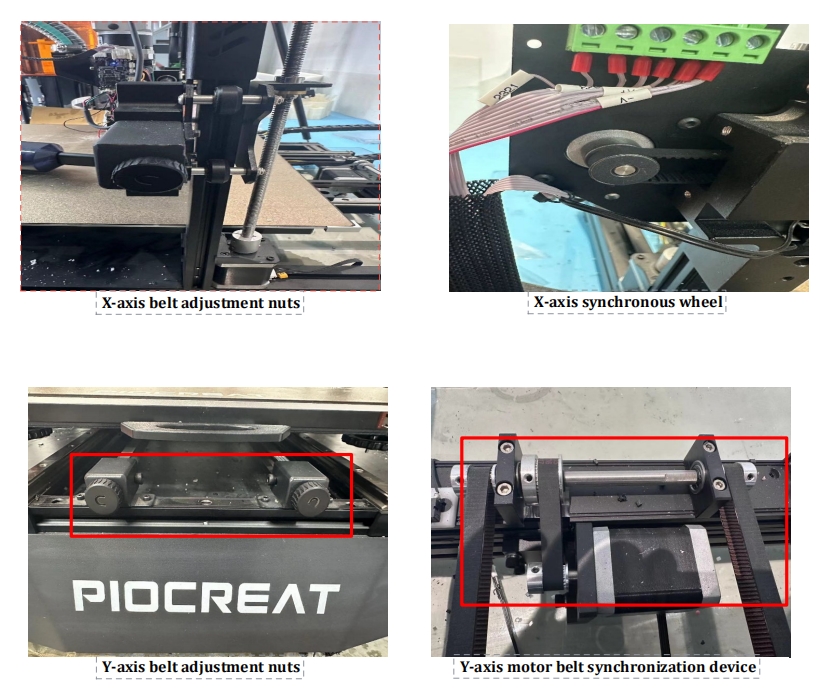

- Mechanical Issues:

- Tighten belts, lubricate lead screws.

- Collapsing/Sagging

- Improve Cooling:

- Max out fan speed for overhangs (but avoid warping).

- Redesign:

- Add internal supports or split the model.

- Supports:

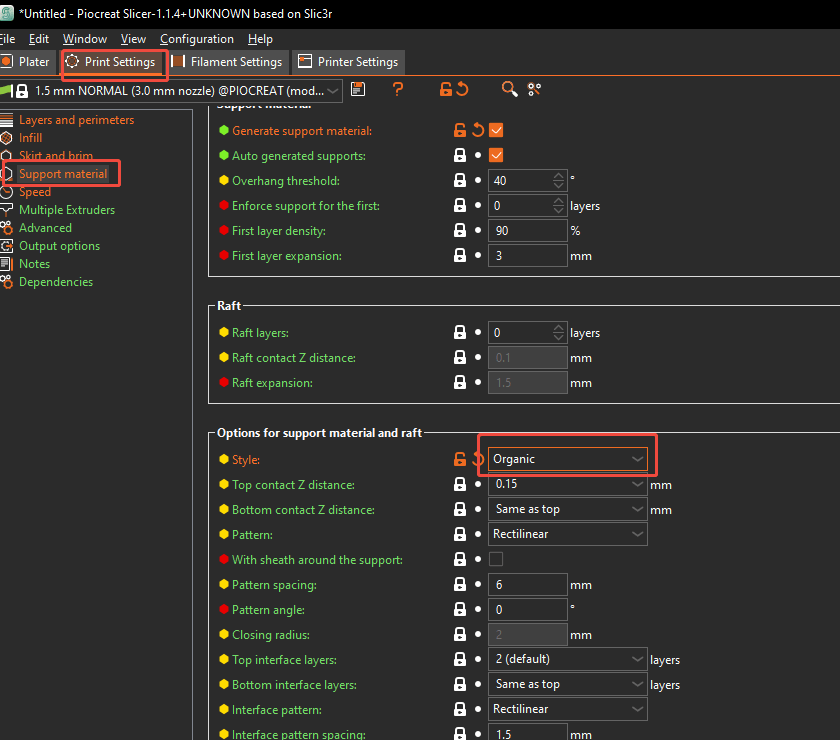

- Use Organic supports for complex model (easier to remove).