Table of Contents

Fused granulate fabrication (FGF) 3D printing technology has expanded the horizons of design and manufacturing, and 3D printed carbon fiber composites enhance these capabilities. This cutting-edge technology enables users in the automotive, aerospace, defense, and manufacturing sectors to swiftly and efficiently create high-strength, temperature-resistant parts with versatile geometries.

Can a 3D Printer Print Carbon Fiber?

Sure, Carbon fiber 3D printers are specifically designed to handle this task. By integrating carbon fiber into the printing process, these printers can produce parts that are stronger and lighter than those made with traditional materials. The most common carbon fiber composites are:

ABS-CF

It is made of ABS raw material as the base material, with additions including carbon fiber, carbon black, and polymer anti-static masterbatch, among others.

PC-CF

PC-CF is based on PC raw materials and is mixed with carbon fiber, carbon black, metal fiber, metal powder, and permanent anti-static masterbatch.

PAHT-CF

RAHT-CF is easy to print, with no warping and high Z-axis strength. It is more chemically resistant than most PA grades and can withstand high temperatures up to 150°C.

What Are the Benefits to 3D Printing with Carbon Fiber?

Chemical and Heat Resistance

One of the most significant advantages of 3D printed carbon fiber composites is their excellent chemical and heat resistance. This makes them ideal for applications that require durability under extreme conditions, such as in the aerospace and automotive industries.

The heat resistance of carbon fiber composites ensures that parts remain stable and retain their mechanical properties even at high temperatures. This characteristic is particularly important in environments like engine compartments or aerospace applications, where components are exposed to elevated temperatures and aggressive chemicals.

High Tensile Strength

Carbon fiber composites are known for their high tensile strength. This property makes them suitable for producing parts that need to withstand high stress and load, ensuring reliability and longevity in demanding applications.

The tensile strength of carbon fiber composites can be several times higher than that of traditional materials like aluminum or steel. This means that parts made from carbon fiber can bear more load without breaking, which is crucial for critical components in various industries.

High Strength-to-Weight Ratio and FST Rating

The strength-to-weight ratio of carbon fiber composites is exceptionally high. This means that parts can be made lighter without compromising on strength, which is crucial in industries like aerospace and automotive where reducing weight can lead to significant performance improvements. Additionally, these materials often have favorable flame, smoke, and toxicity (FST) ratings, making them safer for use in various environments.

A high strength-to-weight ratio allows engineers to design lightweight structures that do not sacrifice performance or durability. This is particularly beneficial in applications like aircraft or high-performance vehicles, where every gram of weight saved can translate to better fuel efficiency and improved handling.

Applications for Carbon Fiber 3D Printed Parts

Automotive

In the automotive industry, carbon fiber 3D printing is used to produce lightweight and strong components, improving fuel efficiency and performance. Examples include custom brackets, supports, and even entire body panels.

The ability to create complex geometries with carbon fiber 3D printing allows for the design of parts that optimize aerodynamics and reduce drag, further enhancing vehicle performance. Additionally, the customization capabilities of 3D printing enable manufacturers to produce parts tailored to specific vehicle models or even individual customer preferences.

Aerospace

The aerospace sector benefits from the high strength-to-weight ratio of carbon fiber composites. This material is used to manufacture critical components like brackets, mounts, and structural parts that must endure high stress and extreme temperatures.

In aerospace applications, every kilogram of weight saved can result in significant cost savings over the lifetime of an aircraft. Carbon fiber 3D printing enables the production of lightweight parts that meet stringent aerospace standards, contributing to overall weight reduction and improved fuel efficiency.

Defense

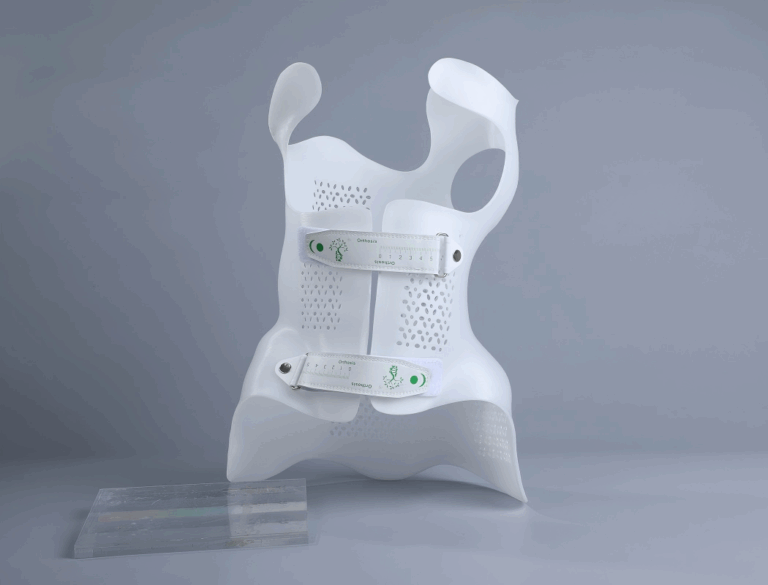

For defense applications, carbon fiber 3D printing allows for the production of durable and lightweight parts that can withstand harsh environments. This includes everything from vehicle components to personal protective equipment.

The high strength and impact resistance of carbon fiber composites make them ideal for military applications where reliability and performance are critical. Additionally, the ability to rapidly produce custom parts using 3D printing ensures that defense contractors can quickly respond to changing requirements and field conditions.

Manufacturing

In manufacturing, carbon fiber 3D printing is used to create strong and durable tools, jigs, and fixtures. This not only speeds up the production process but also reduces costs by minimizing downtime and the need for frequent replacements.

The versatility of carbon fiber 3D printing allows manufacturers to produce custom tooling and fixtures tailored to specific production needs. This can lead to improved efficiency and reduced cycle times, enhancing overall productivity and competitiveness.

What 3D Printers Can Print Carbon Fiber?

G12 Pellet 3D Printer

The G12 Pellet 3D Printer is a large-format pellet extrusion printer capable of printing medium-to-large format parts with ease. Boasting a massive build volume of 1200x1000x1000mm, its high-temperature capabilities and rapid heating make it suitable for printing with carbon fiber composites.

The G12’s large printing volume allows for the production of sizable components in a single print, reducing the need for assembly and enhancing the structural integrity of the final product. The high nozzle temperature and rapid heating ensure that the carbon fiber composite material is processed efficiently, resulting in high-quality prints with excellent mechanical properties.

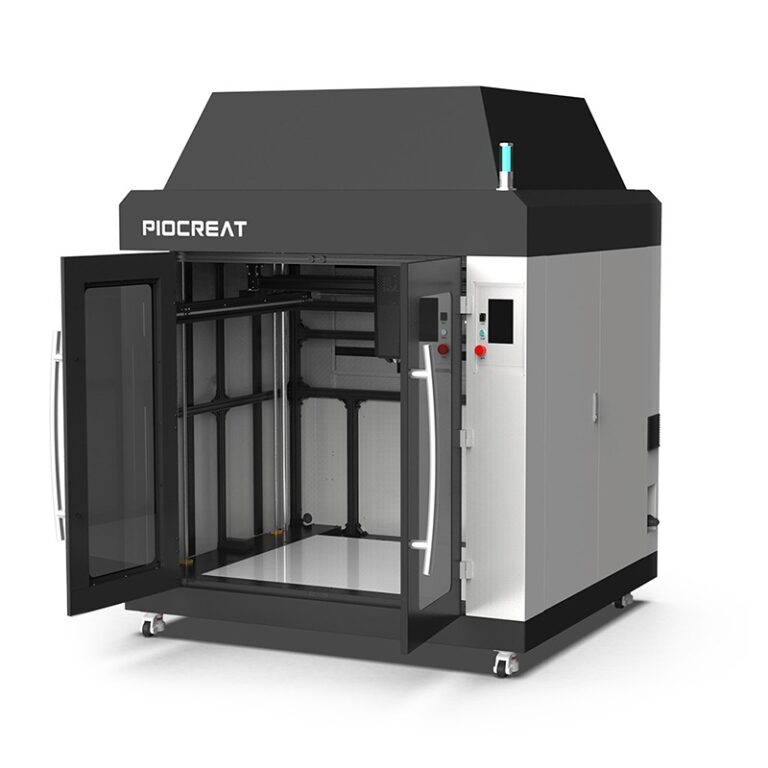

G40 Pellet 3D Printer

The G40 Pellet 3D Printer, PioCreat’s largest industrial printer, is a versatile and reliable industrial additive and CNC five-axis manufacturing integrated machine. It is ideal for large-scale 3D printing, offering the flexibility and precision needed for high-performance carbon fiber composite parts.

The G40’s combination of additive manufacturing and CNC capabilities allows for the production of complex parts with high precision. The large working space makes it possible to print large components or multiple parts simultaneously, increasing efficiency and throughput. The CNC five-axis head provides additional flexibility, enabling the production of parts with intricate geometries and fine details.

Conclusion

Carbon fiber 3D printing represents a significant advancement in the manufacturing and design industries, offering unparalleled benefits in terms of strength, weight, and resistance. From automotive and aerospace to defense and general manufacturing, the applications are vast and transformative. With cutting-edge printers like the G12 and G40 Pellet 3D Printers, businesses can leverage the full potential of this technology, pushing the boundaries of what is possible in their respective fields.

The future of manufacturing is being reshaped by the capabilities of carbon fiber 3D printing. As technology continues to evolve, the accessibility and affordability of these advanced materials and processes will only improve, enabling more industries to benefit from the advantages of lightweight, high-strength, and durable components. Whether you’re looking to enhance performance, reduce costs, or innovate in design, carbon fiber 3D printing offers the tools and capabilities to achieve your goals.