Carbon fiber 3D printing is revolutionizing industries by combining the versatility of additive manufacturing with the exceptional properties of carbon fiber composites. This innovative technology allows manufacturers to produce parts that are stronger, lighter, and more durable than traditional materials, all while reducing costs and production times.

In this blog post, we’ll dive into what carbon fiber 3D printing is, explore common carbon fiber composites, and discuss the benefits and applications of this cutting-edge technology. We’ll also highlight 3D printers designed specifically for carbon fiber printing and why pellet-based systems are leading the way.

What Is Carbon Fiber 3D Printing?

Carbon fiber 3D printing involves reinforcing traditional 3D printing materials with short or continuous carbon fibers. These fibers significantly enhance the strength, stiffness, and thermal resistance of the base material, making it suitable for demanding applications across various industries.

There are two main approaches to carbon fiber 3D printing:

- Short Fiber Reinforcement: Short strands of carbon fibers are mixed into the material, such as ABS or polycarbonate, creating composites like ABS-CF or PC-CF.

- Continuous Fiber Reinforcement: Long, continuous carbon fibers are embedded within the print, offering unparalleled strength for structural applications.

The process is compatible with advanced 3D printers that can handle high-temperature materials and provide precise extrusion control.

The Most Common Carbon Fiber Composites

Carbon fiber composites vary in their properties and applications based on the base material. Below are three of the most commonly used types:

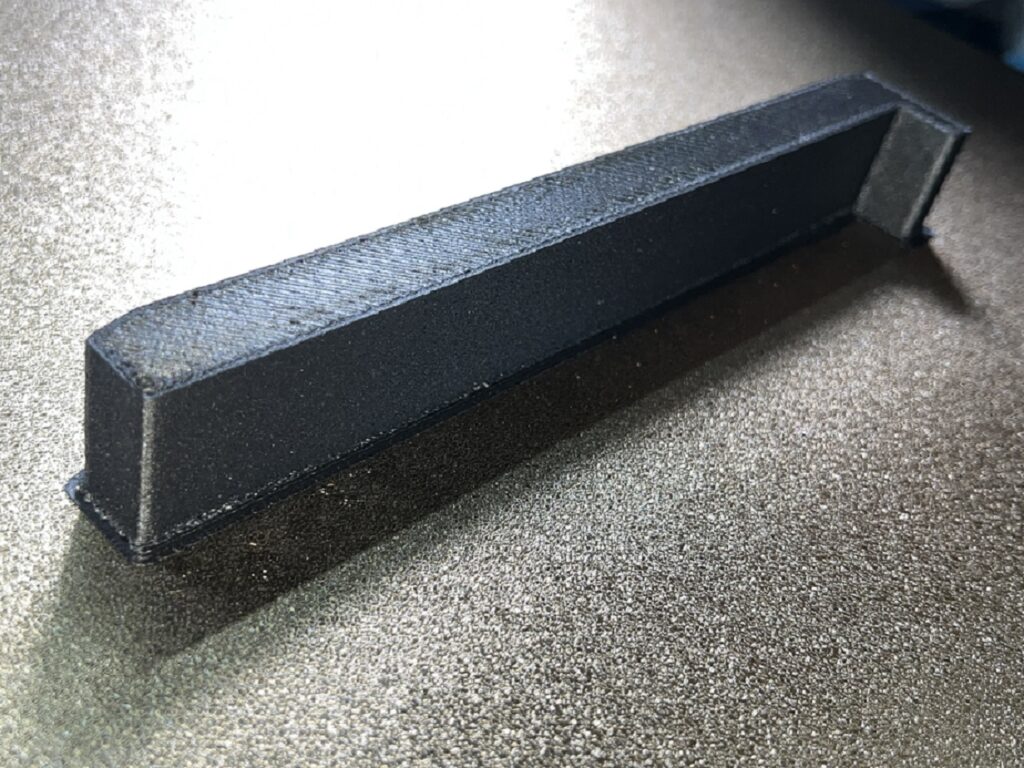

1. ABS-CF

ABS-CF (Acrylonitrile Butadiene Styrene with Carbon Fiber) combines ABS, a widely used thermoplastic, with carbon fiber for enhanced durability and performance.

Applications:

- Stylus pens

- Chip trays

- Electronic component packaging boards

Key Features:

- Anti-static properties: Protects sensitive electronics from static discharge.

- Static dissipation and conductivity: Useful for electronic housings.

- Electromagnetic interference (EMI) shielding: Adds protection for electronic devices.

2. PC-CF

PC-CF (Polycarbonate with Carbon Fiber) pairs polycarbonate with carbon fiber for exceptional strength and impact resistance, making it ideal for demanding environments.

Applications:

- Tweezers

- Camera casings

- Appliance housings

- Electronic spare parts

Key Features:

- High mechanical strength: Ideal for structural components.

- Impact resistance: Withstands heavy usage.

- Anti-static and static dissipation: Great for precision applications in electronics.

3. PAHT-CF

PAHT-CF (High-Temperature Polyamide with Carbon Fiber) is a high-performance material that resists warping and maintains its structural integrity under extreme conditions.

Applications:

- Industrial jigs and fixtures

- Automotive parts

- Drone components

Key Features:

- Chemical resistance: Suitable for harsh environments.

- High dimensional stability: Ensures reliable performance.

- Withstands temperatures up to 150°C: Ideal for high-heat applications.

- Low hygroscopicity: Improves durability in humid conditions.

Benefits of Carbon Fiber 3D Printing

1. Stronger Yet Lighter

Carbon fiber composites offer a superior strength-to-weight ratio, making them perfect for industries like aerospace and automotive, where reducing weight without compromising strength is critical.

2. Resistance to Wear and Tear

Parts printed with carbon fiber composites are highly durable, offering excellent resistance to wear, impact, and thermal stress.

3. Versatile Applications

From precision medical devices to large-scale industrial tooling, carbon fiber 3D printing caters to a wide range of industries and use cases.

4. Eco-Friendly and Efficient

3D printing minimizes waste compared to traditional subtractive manufacturing methods, and using pellets further reduces costs and environmental impact.

Applications: Where Carbon Fiber 3D Printing Shines

1. Aerospace and Aviation

Lightweight yet strong components are essential in aerospace applications. Carbon fiber’s thermal resistance and durability make it ideal for parts like brackets, housings, and structural supports in planes and spacecraft.

2. Automotive Industry

Carbon fiber allows for the production of lighter vehicle components, improving fuel efficiency while maintaining safety and performance standards. Examples include dashboards, engine covers, and suspension components.

3. Industrial Tooling

Custom jigs, fixtures, and molds can be printed quickly and affordably. Carbon fiber’s durability ensures these tools last longer and perform better than those made from traditional materials.

4. Medical Devices

Carbon fiber’s biocompatibility and lightweight nature make it an excellent choice for prosthetics, orthopedic implants, and surgical instruments.

What 3D Printers Can Print Carbon Fiber?

Not all 3D printers are equipped to handle the demands of carbon fiber composites. High-performance printers with specific features like high-temperature nozzles and robust extrusion systems are required.

PioCreat G12 Pellet 3D Printer

The G12 is an industrial-scale 3D printer perfect for medium-to-large format parts.

Key Features:

- Build Volume: 1200×1000×1000mm

- Nozzle Temperature: Up to 450°C for advanced materials.

- Rapid Bed Heating: Heats up to 120°C to prevent warping.

- High Flow Screw Extrusion: Efficient material deposition.

- Applications: Ideal for industrial components, furniture, and molds.

PioCreat G40 Pellet 3D Printer

The G40 is designed for oversized projects and multi-process manufacturing.

Key Features:

- Build Volume: 3725×2500×1330mm, among the largest in the industry.

- CNC Five-Axis Head: Enables complex, multi-process applications.

- High Flow Screw Extrusion: Supports rapid production of large-scale parts.

- Applications: Suitable for aerospace components, large molds, and architectural designs.

Why Choose Pellet-Based Carbon Fiber 3D Printing?

Pellet-based systems like the G12 and G40 offer significant advantages over filament-based systems for carbon fiber 3D printing:

Cost Efficiency

Pellets are more affordable than filaments, especially for large-scale projects. This makes pellet-based printing an economical choice for industrial applications.Scalability

Pellet systems handle larger build volumes, allowing for the creation of large parts like furniture, automotive panels, or structural components.Material Versatility

Pellet-based printers can work with a wider range of composites, including carbon fiber-reinforced ABS, PC, and PAHT, providing flexibility for various industries.