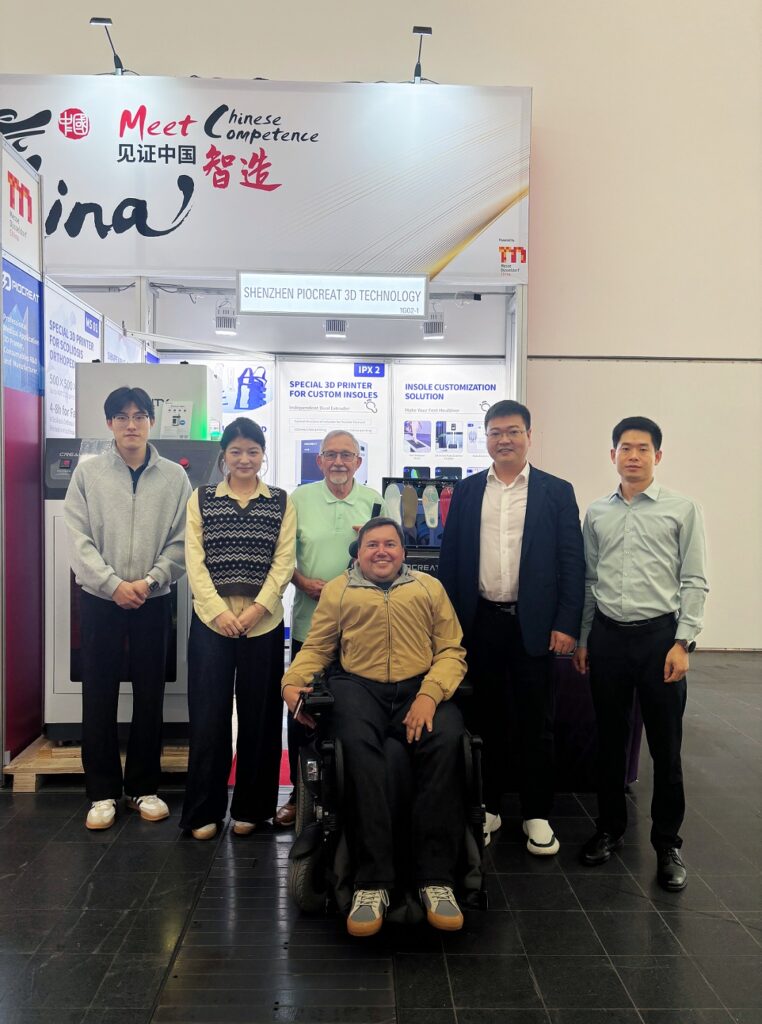

PioCreat & Creality to Showcase Innovations at Formnext 2024

piocreat3d

on

October 15, 2024

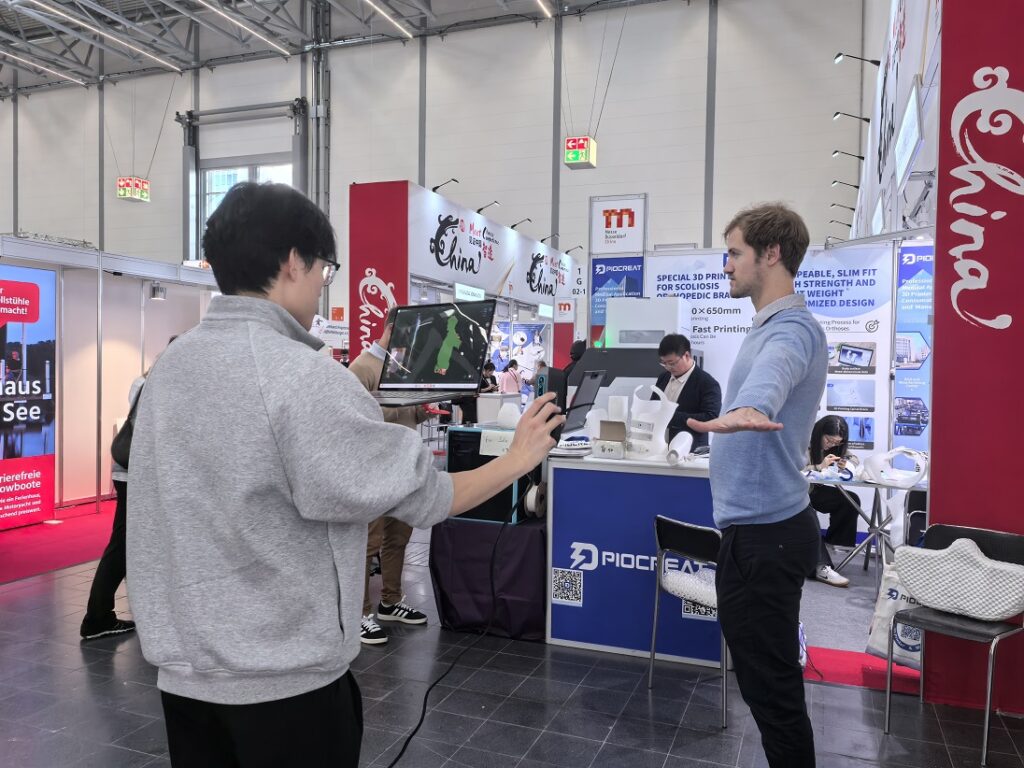

PioCreat and Creality are excited to announce our participation in Formnext Frankfurt 2024, the world’s leading hub for Additive Manufacturing and industrial 3D printing. Join us from November 19-22, 2024, at the Messe Frankfurt Exhibition Center, Hall 12.1, and visit our booth 121-C02 to discover our latest 3D printing innovations.

About Formnext

As a key industry platform, Formnext connects professionals and experts across the globe, providing up-to-date industry knowledge and networking opportunities for additive manufacturing (AM) specialists. It is the go-to event for discovering the latest advances in industrial 3D printing technologies and production solutions. Formnext promotes in-depth professional exchange, offering access to cutting-edge AM solutions and trends from various application industries.

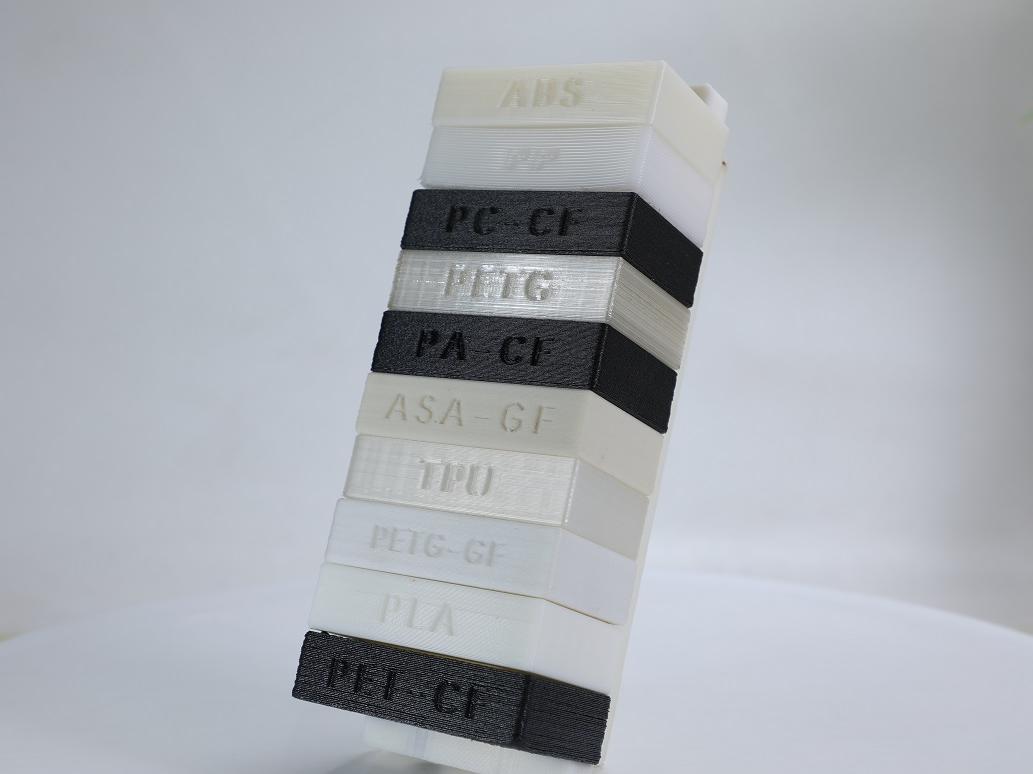

PioCreat’s Pellet 3D Printing Solutions

At Formnext, PioCreat will showcase our advanced Pellet 3D Printing Solutions, a sustainable and cost-efficient technology that includes:

- Pellet 3D Printer + Pellet Material + Dryer

Our key products include:

- Desktop | Build Volume: 500×500×400mm

- The G5Ultra is an eco-friendly desktop printer that uses both virgin and recycled pellets, significantly reducing material costs and promoting a circular economy.

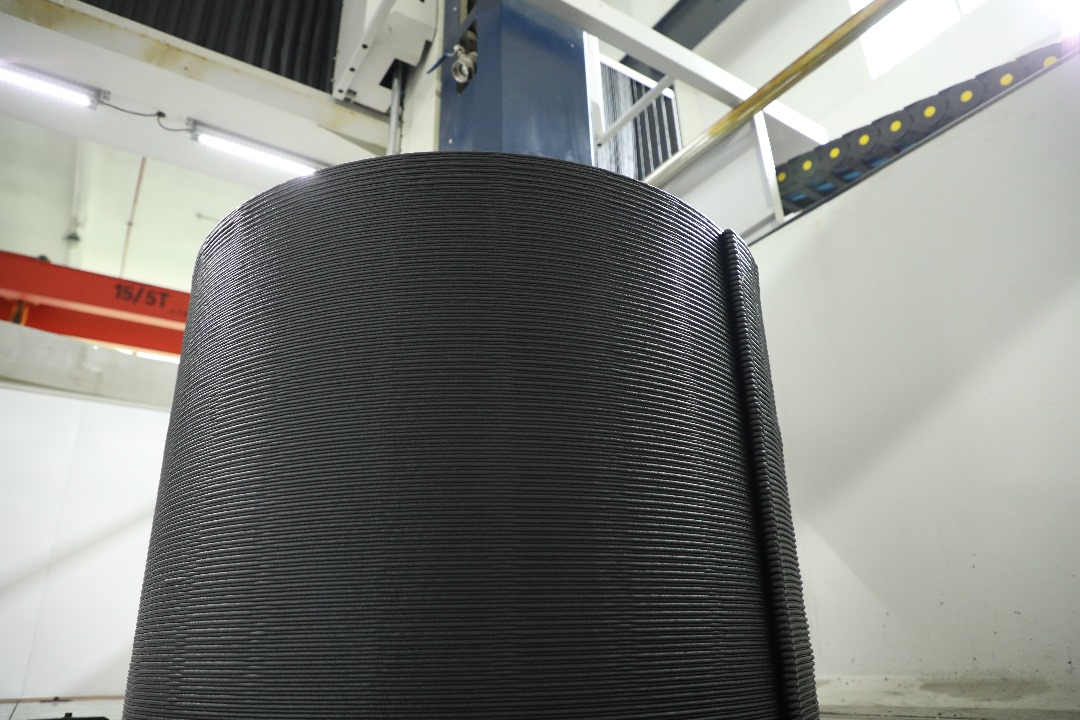

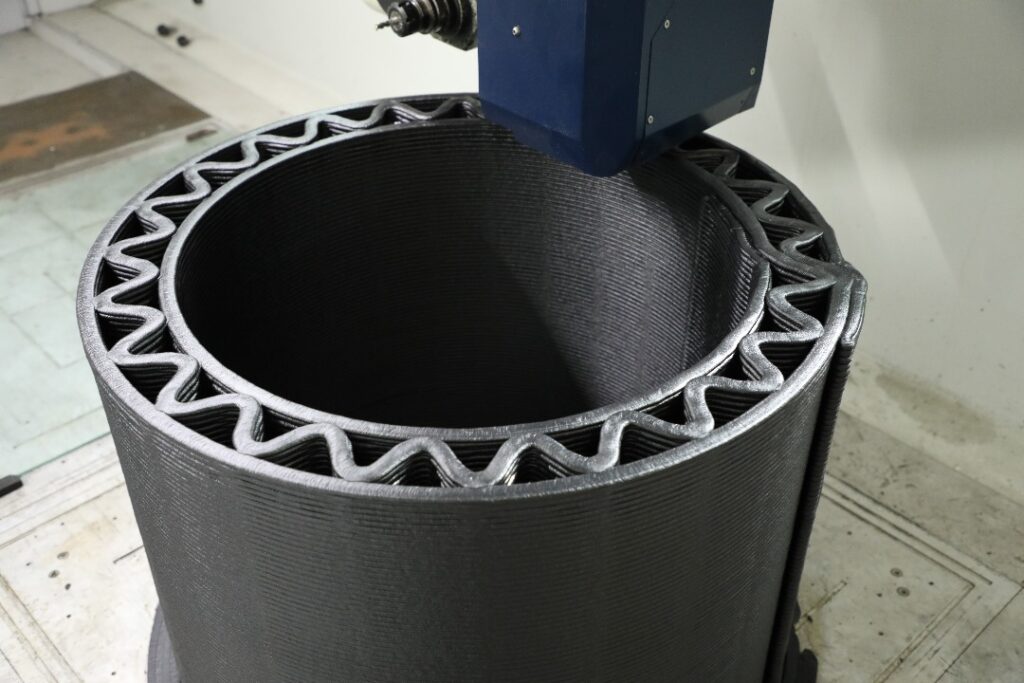

G12 Large-Scale Pellet 3D Printer

- Build Volume: 1200×1000×1000mm

- The G12 Fused Granulate Fabrication (FGF) printer is designed for large-scale, high-speed thermoplastic extrusion, making it ideal for manufacturing large prototypes, molds, tooling, and batch production runs.

MS 01 High-Temperature Pellet 3D Printer

- Specially designed for custom healthcare solutions, the MS 01 is particularly effective for spinal orthotics for scoliosis, offering personalized care and tailored support to meet individual needs. This printer helps advance customization in the healthcare industry, making personalized solutions more accessible.

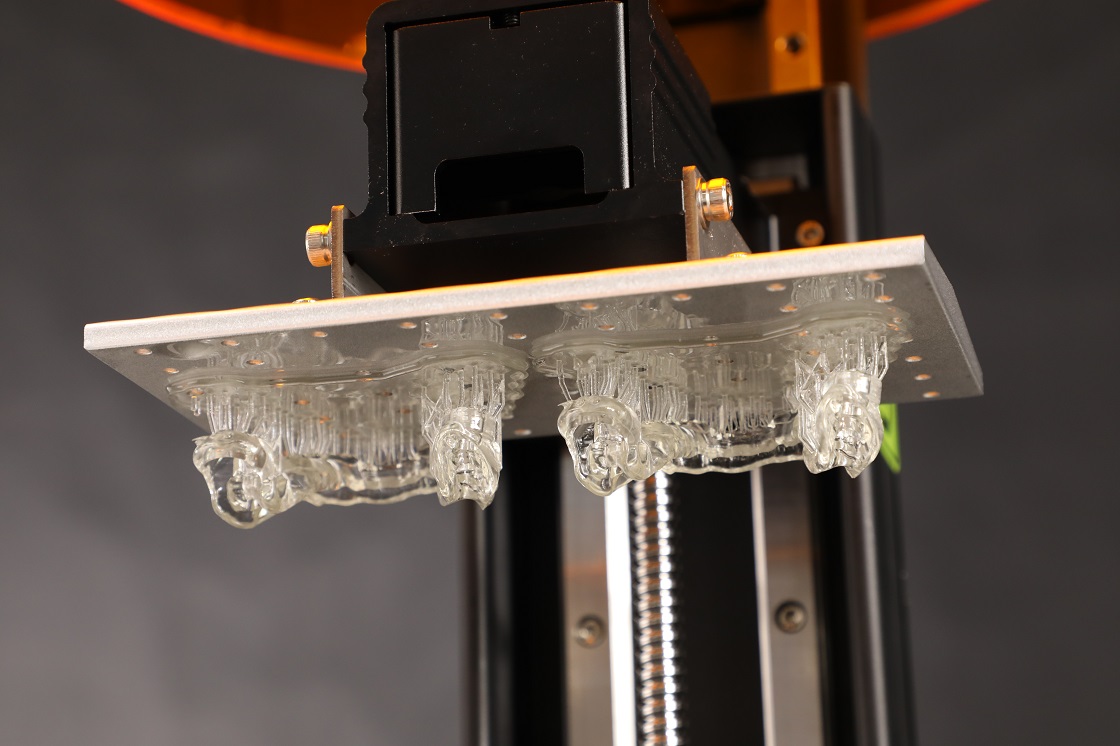

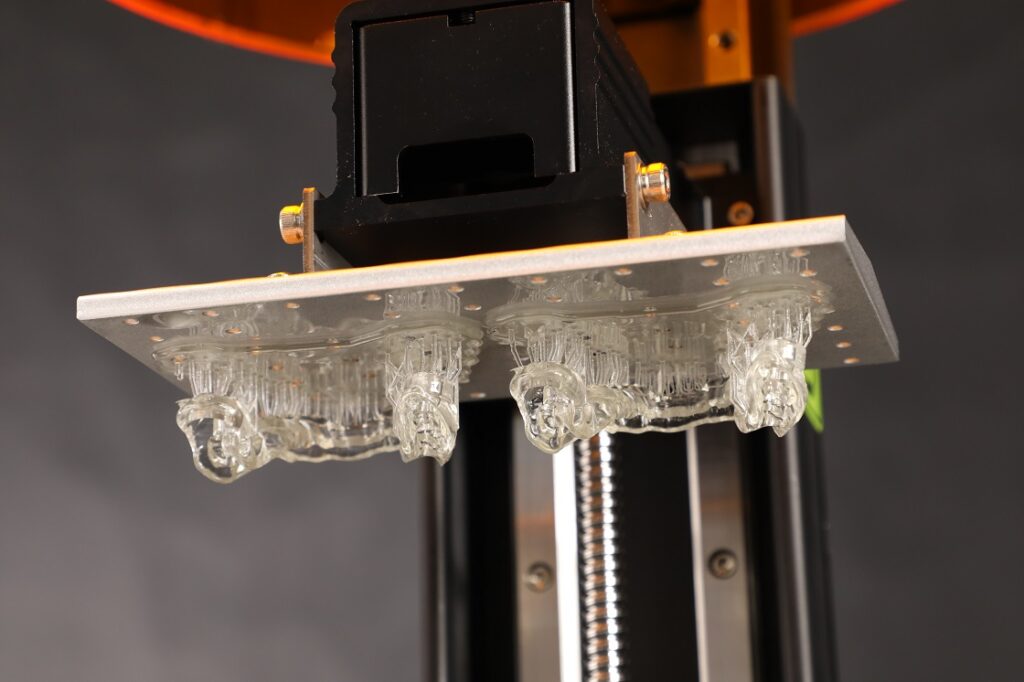

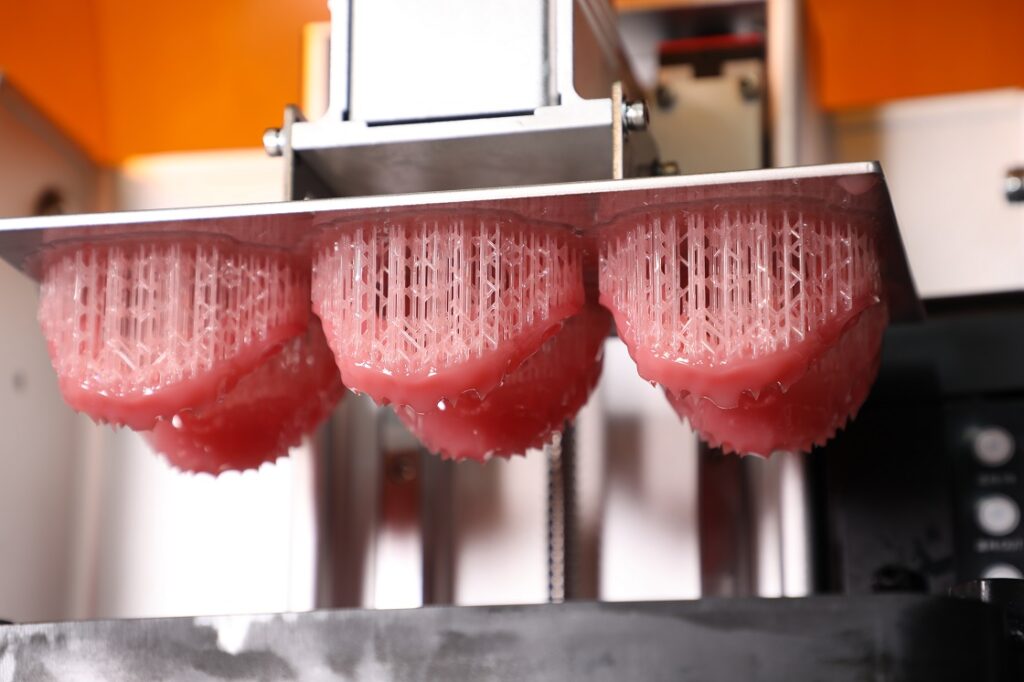

PioCreat’s Dental 3D Printing Solutions

PioCreat will also feature our advanced Dental 3D Printing Solutions, providing a complete digital workflow that includes:

- 3D Printers + Dental Resin + Cleaning Machines + UV Curing Machines

Our flagship products, such as the DJ89PLUS and D158, combined with the UV02 post-processing tool, offer fast, accurate, and cost-effective solutions for dentists, orthodontists, and labs. These products outperform traditional methods, delivering robust and high-quality dental appliances with improved precision.

About PioCreat

A specialist in industrial 3D printers and a subsidiary of Creality, Founded in 2015 and based in Shenzhen, China. PioCreat provide innovative and tailored solutions that cater to the diverse needs of industries including healthcare, dental, automotive, and manufacturing.

About Creality

Creality, a global leader in consumer 3D printing. Since 2014, Creality has been recognized for its dedication to innovation and the popularization of 3D printing technology. With PioCreat, the company extends its expertise to provide advanced solutions for professional, industrial, and dental sectors.

Join us at Formnext Frankfurt 2024 to experience how our 3D printing solutions are transforming industries and shaping the future of additive manufacturing!