Jigs & Fixtures I Mold tooling I Manufacturing validation

Additive manufacturing simplifies production workflows, reducing steps, material use, and time, making complex parts easier and faster to produce.

Ideal for small batches, additive manufacturing enables affordable, on-demand production without the need for expensive molds or setup costs.

Quickly create and test designs with 3D printing, allowing faster iteration and improvements, which accelerates development and reduces project timelines.

Explore intricate, customized designs without the constraints of traditional manufacturing, unlocking new possibilities for innovation and creativity.

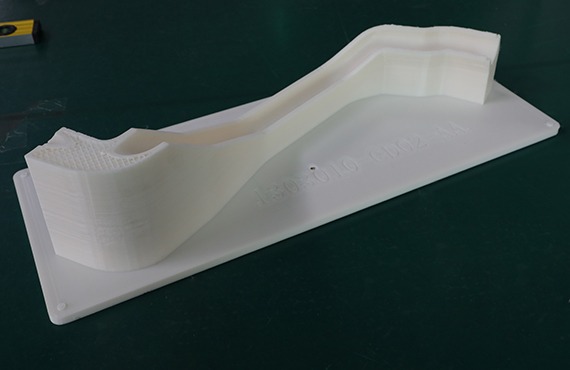

Enhancing the crafting of molds, and prototyping for perfect fit checks.

Copyright © 2024 PioCreat 3D Technology Co., Ltd. All Rights Reserved.