Table of Contents

Large scale 3D printing is transforming the way industries approach manufacturing, providing an efficient and cost-effective solution for producing large, complex structures. With advancements in technology, large scale 3D printers are now capable of creating everything from massive sculptures to functional industrial parts. In this blog, we’ll explore what large scale 3D printing is, what qualifies as a large format 3D printer, the benefits it offers, its applications, and some of the best large scale 3D printers available today.

What is Large Scale 3D Printing?

Large scale 3D printing refers to the process of creating sizeable objects using 3D printing technology. Unlike traditional 3D printers designed for small, detailed models, large scale 3D printers can produce items with dimensions reaching several meters. This capability is invaluable for industries such as construction, automotive, aerospace, and art, where large and complex parts are often required. By leveraging large scale 3D printing, manufacturers can achieve greater efficiency and innovation in their production processes.

Large scale 3D printing is not just an extension of conventional 3D printing but a significant leap in manufacturing capabilities. It enables the creation of prototypes, functional parts, and even end-use products that would otherwise be difficult or impossible to manufacture using traditional methods. This technology can handle various materials, from plastics and resins to metals and concrete, allowing for a wide range of applications.

What is Considered a Large Format 3D Printer?

A large format 3D printer is characterized by several key features that enable it to handle the production of large objects effectively:

Bigger Build Volume

The most distinguishing feature of a large format 3D printer is its extensive build volume. These printers can produce objects that are significantly larger than what standard 3D printers can handle, often exceeding dimensions of 1000mm in one or more axes. For instance, the G12 Pellet 3D Printer has a build volume of 1200x1000x1000mm, which allows it to print substantial parts in a single run, eliminating the need for assembly.

Heated Print Bed

A heated print bed is essential for maintaining the adhesion of the first layer of the print. This feature is particularly important for large scale prints to prevent warping and ensure a stable foundation for the entire build. A heated bed ensures that the material remains at an optimal temperature throughout the printing process, which is crucial for achieving high-quality prints.

Industrial-Grade Components

Large format 3D printers are built with industrial-grade components, including robust frames, powerful motors, high-quality extruders, and advanced control systems. These components ensure the printers can handle the demands of producing large, complex parts with high precision and reliability. For example, the G40 Pellet 3D Printer features a CNC five-axis head, high flow screw extrusion design, and a large working space, making it suitable for complex industrial applications.

What are the Benefits of Large Format 3D Printing?

Large format 3D printing offers numerous advantages, making it a preferred choice for many industries:

Larger Build Volume

The ability to print larger objects in one piece eliminates the need for assembling smaller parts, resulting in stronger and more cohesive structures. This advantage is particularly useful in the automotive and aerospace industries, where the integrity and strength of large components are critical.

Reduced Assembly Requirements

Printing large components as a single piece significantly reduces the need for assembly, saving time and minimizing potential weak points where parts are joined together. This reduction in assembly not only speeds up production but also enhances the overall durability of the final product.

Cost Efficiency

Large scale 3D printing is often more cost-effective than traditional manufacturing methods. It reduces material waste, eliminates the need for expensive molds, and allows for rapid prototyping, leading to overall cost savings. By streamlining the production process, companies can achieve significant cost reductions, making it an attractive option for small and large businesses alike.

Time Savings

The speed of large scale 3D printing can drastically reduce production times. Traditional manufacturing processes such as mold making and assembly are time-consuming, whereas 3D printing can create the final product directly from the digital model. This rapid turnaround is especially beneficial for industries that need to bring products to market quickly or respond to urgent production demands.

What is a Large Format 3D Printer Used For?

Large format 3D printers are used in various applications that benefit from their ability to produce large and intricate designs:

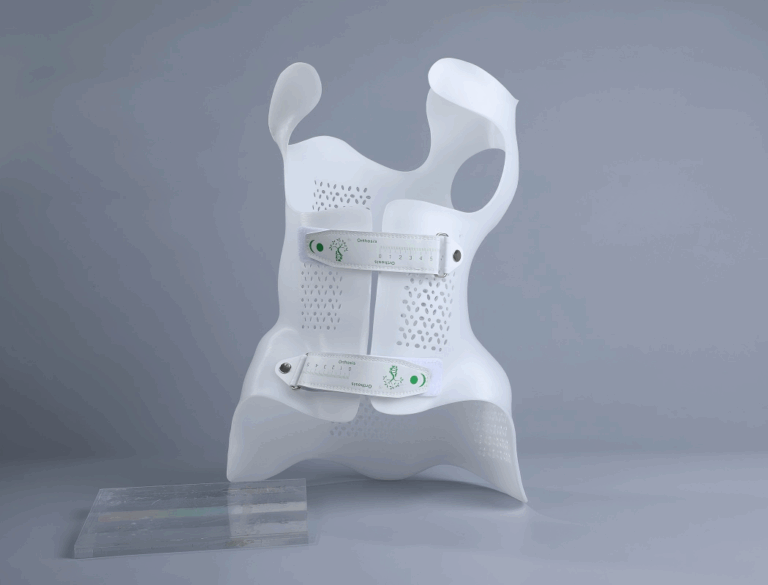

Large-Scale Art and Sculptures

Artists and sculptors use large scale 3D printers to create massive, detailed works of art that would be difficult or impossible to produce by hand. This technology allows artists to bring their visions to life on a grand scale, pushing the boundaries of creativity and innovation.

Tooling and Fixtures

In industrial settings, large scale 3D printers are used to create custom tooling and fixtures that are essential for manufacturing processes, improving efficiency and precision. These tools can be tailored to specific tasks, enhancing productivity and reducing production times.

Rapid Prototyping

Large scale 3D printing is ideal for rapid prototyping of large parts, allowing designers and engineers to test and refine their ideas quickly and cost-effectively. This capability is crucial for industries that require frequent design iterations and fast development cycles, such as automotive and aerospace.

Aerospace

The aerospace industry benefits greatly from large scale 3D printing, which allows for the manufacturing of large, high-strength composite parts for aircraft. This capability not only enhances the performance and durability of aerospace components but also reduces the weight of the aircraft, leading to better fuel efficiency and overall performance.

Maritime

The maritime sector is also embracing the flexibility of large scale 3D printing. This technology is used to create large parts for shipbuilding and perform at-sea maintenance. By producing custom parts on demand, 3D printing helps maintain ships’ operational efficiency and reduces downtime.

Best Large Scale Industrial 3D Printers

Here are two of the best large scale 3D printers known for their advanced features and reliable performance:

G12 Pellet 3D Printer

- Printing Size: 1200x1000x1000mm

- Features:

- Nozzle temperature up to 450℃

- Rapid heating of hot bed up to 120℃

- High Flow Screw Extrusion

- Powerful Servo Motor

The G12 Pellet 3D Printer is a large-format pellet extrusion printer capable of printing medium-to-large parts with high precision and speed. Its robust design and advanced features make it ideal for industrial applications. The G12’s ability to handle a wide range of materials, including thermoplastics and composites, makes it a versatile tool for various manufacturing needs.

G40 Pellet 3D Printer

- Printing Size: 3725x2500x1330mm

- Features:

- Large working space

- Workbench design

- CNC five-axis head

- High flow screw extrusion design

The G40 Pellet 3D Printer, Piocreat’s largest industrial printer, combines versatility and reliability. It is suitable for industrial-scale projects, offering a large working area and advanced CNC capabilities for creating complex and large-scale components. The G40’s precision and flexibility make it ideal for applications that require high-quality, detailed prints on a large scale.

Wrapping Up

Large scale 3D printing is revolutionizing various industries by enabling the efficient production of large, complex structures. With benefits such as larger build volumes, reduced assembly requirements, cost efficiency, and diverse applications, this technology is paving the way for innovation and productivity. The G12 and G40 Pellet 3D Printers are among the best options available for those looking to leverage the power of large scale 3D printing in their operations. As technology continues to evolve, the potential for large scale 3D printing will only expand, offering new opportunities for creative and industrial applications.