We’re thrilled to announce that CDG 3D TECH has officially become the UK distributor for PioCreat’s cutting-edge FGF pellet 3D printers, solidifying this partnership during Formnext 2024. This collaboration marks an exciting milestone for both companies as we bring the benefits of Fused Granulate Fabrication (FGF) technology to the UK market.

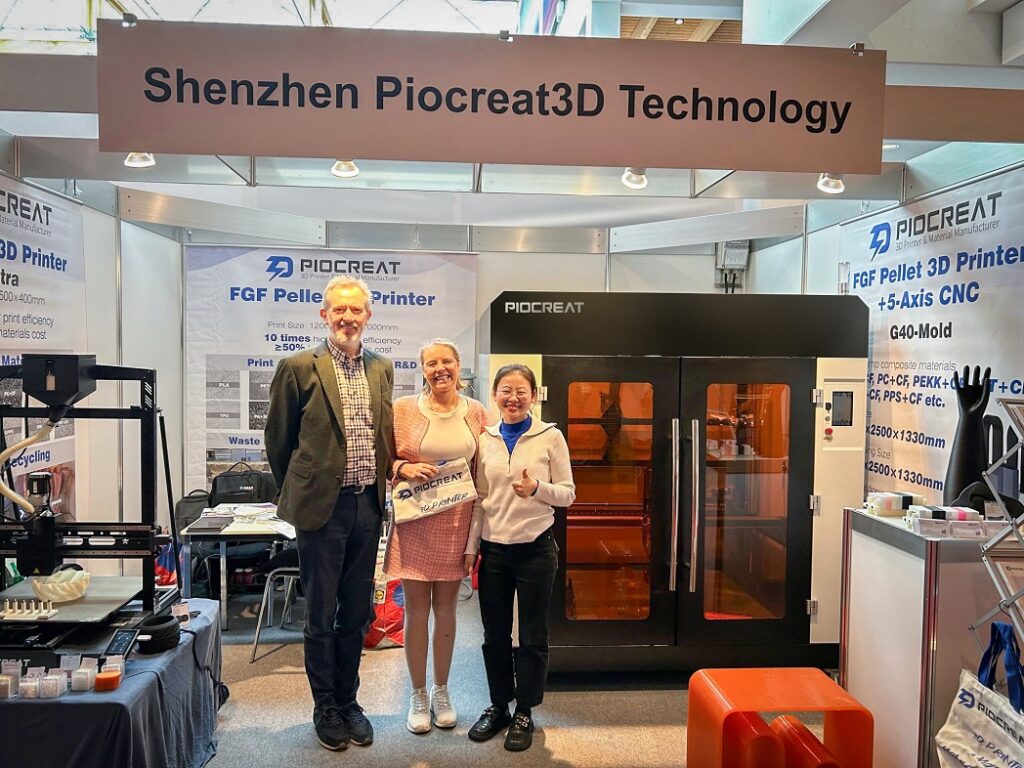

CDG 3D TECH’s CEO and his wife at Fakuma 2024

Why FGF Pellet Printing?

FGF pellet 3D printing represents a significant leap in additive manufacturing, offering unparalleled speed, versatility, and scalability. This technology allows users to:

- Print Faster: FGF technology enables high-speed production, drastically reducing print times compared to traditional methods.

- Leverage Material Versatility: By using open-source thermoplastic pellets, manufacturers can print in a wide range of materials, including engineering-grade and sustainable options.

- Produce Large Parts: FGF printers excel at creating sizable components such as tooling, molds, and prototypes with industrial-grade precision.

Piocreat’s FGF Pellet 3D Printer Range

CDG 3D TECH will offer a comprehensive lineup of Piocreat’s industry-leading FGF pellet 3D printers, each designed to meet a variety of manufacturing needs:

1. G5Ultra

A compact yet powerful solution for high-speed, cost-effective production.

- Key Features:

- Nozzle temperature up to 420℃ for advanced material compatibility.

- Rapid hot bed heating up to 120℃ ensures warp-free prints.

- Screw extruder design accommodates diverse thermoplastic materials.

- Ideal For: Prototyping, educational labs, and design studios.

2. G12

Designed for large-scale additive manufacturing, the G12 combines speed with scale.

- Key Features:

- Build volume ideal for sizable patterns, molds, and batch production runs.

- Optimized for industrial applications such as tooling, jigs, and full-scale prototypes.

- Ideal For: Automotive, aerospace, and manufacturing sectors.

3. G40

A hybrid machine that integrates large-scale 3D printing and CNC five-axis manufacturing.

- Key Features:

- Combines additive and subtractive processes to produce near-finished parts.

- Capable of milling workpieces to precise specifications.

- Ideal For: Industries requiring high-precision, large-format parts, such as construction and heavy manufacturing.

4. MS01

Piocreat’s latest innovation, designed for high-temperature engineering materials.

- Key Features:

- Chamber temperature up to 100°C for advanced material performance.

- Build size of up to 650mm for medium-scale parts.

- Ideal For: Applications demanding engineering-grade materials in industries like healthcare and engineering.

New MS01 FGF pellet 3D printer with heated chamber

About CDG 3D TECH

As a leading UK supplier of 3D printing, additive manufacturing, 3D scanning, and 3D software solutions, CDG 3D TECH brings unparalleled expertise to this partnership. With a strong reputation for delivering innovative solutions and exceptional customer support, CDG is the ideal partner to bring Piocreat’s FGF technology to manufacturers across the UK.

CDG 3D TECH Showcasing Pellet 3D printers at UK Exhibition

A Partnership Built for Success

By teaming up with CDG, Piocreat expands its global footprint, offering UK businesses access to the transformative power of FGF pellet 3D printing. Together, we are committed to driving innovation and delivering solutions that help manufacturers reduce costs, increase productivity, and embrace sustainable practices.

Stay tuned for more updates as this partnership brings new opportunities to the UK’s 3D printing and additive manufacturing industries.