The world of 3D printing has seen significant advancements, and carbon fiber reinforced pellets are transforming the potential of Fused Granulate Fabrication (FGF) 3D printing. By blending carbon fiber with materials like ABS, PC, and PAHT, these composite pellets create parts that are stronger, lighter, and more durable, opening up new applications in industries such as automotive, aerospace, and manufacturing.

This blog will explore the essentials of FGF 3D printing, the unique properties of carbon fiber reinforced pellets, and the types of materials available, as well as their applications in high-stress environments.

What is FGF 3D Printing?

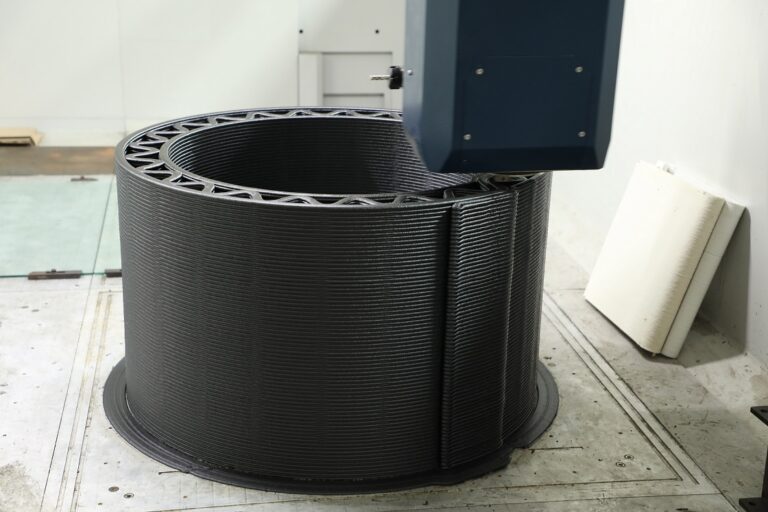

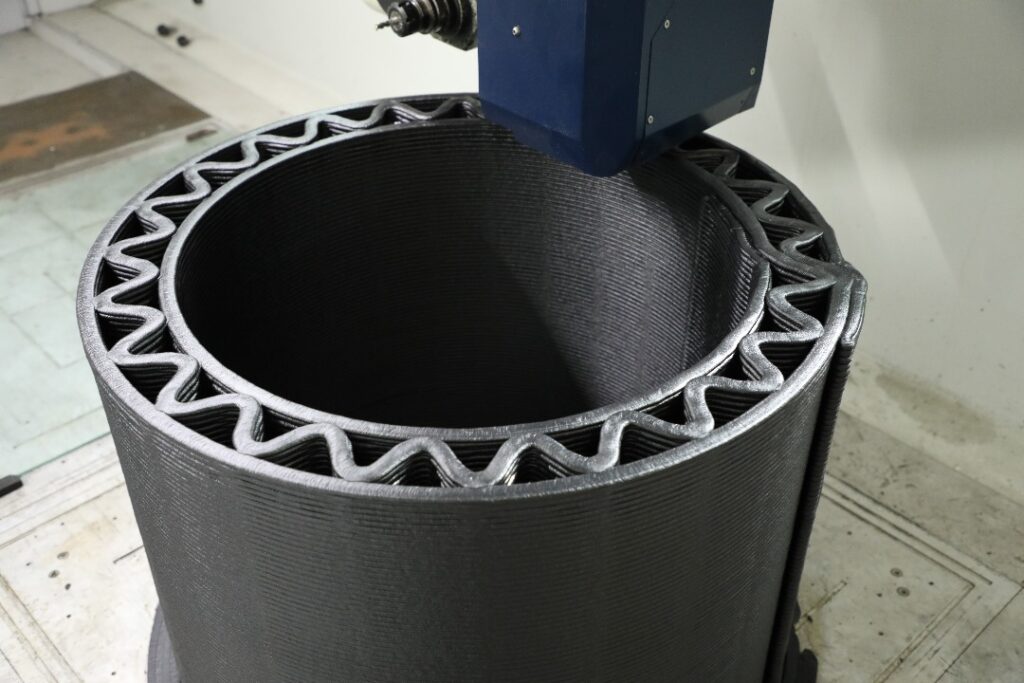

Fused Granulate Fabrication (FGF) is a 3D printing technology that uses thermoplastic pellets as its primary material instead of traditional filament. The process involves feeding these granulated thermoplastics into an extruder, where they’re melted and deposited layer by layer to create the final object. This additive approach enables high-speed production of large, industrial-scale parts while minimizing material costs, making it ideal for sectors like manufacturing, aerospace, and automotive.

FGF’s compatibility with carbon fiber reinforced pellets adds further value, allowing for the creation of parts with high strength, impact resistance, and light weight. These reinforced pellets bring advanced mechanical properties that make FGF 3D printing viable for applications requiring durability and structural integrity, often at a fraction of the cost and production time of traditional manufacturing.

Carbon Fiber Reinforced 3D Printing Pellets

Carbon fiber reinforced pellets combine a thermoplastic base material (such as ABS, PC, or PAHT) with carbon fiber additives. The result is a composite that offers superior strength-to-weight ratio, heat resistance, impact resistance, and electrical conductivity. Let’s look at some popular carbon fiber reinforced materials for FGF printing and their distinct properties.

1. ABS-CF (Acrylonitrile Butadiene Styrene with Carbon Fiber)

ABS-CF is a composite based on ABS (Acrylonitrile Butadiene Styrene), which is mixed with carbon fiber, carbon black, and polymer anti-static masterbatch. This blend provides ABS with enhanced strength and functionality, making it suitable for applications that demand static dissipation and electromagnetic interference (EMI) shielding.

- Anti-static properties: ABS-CF dissipates static electricity, which is beneficial in environments where static buildup could damage sensitive electronics.

- Conductivity: Carbon fiber within ABS-CF provides a degree of conductivity, which enhances its performance in shielding applications.

- Electromagnetic interference (EMI) shielding: ABS-CF’s ability to absorb and block electromagnetic waves makes it suitable for creating parts that protect electronic equipment from interference.

ABS-CF is ideal for applications that require durable, static-dissipative parts with moderate conductivity, making it popular in electronics and manufacturing aids for environments with EMI sensitivity.

2. PC-CF (Polycarbonate with Carbon Fiber)

PC-CF is a composite of polycarbonate (PC) mixed with carbon fiber, carbon black, metal fiber, metal powder, and anti-static agents. Known for its high mechanical strength and impact resistance, PC-CF is suited for applications that need parts capable of withstanding high stress and mechanical loads.

- High mechanical strength: PC-CF provides excellent strength and rigidity, making it ideal for load-bearing components.

- Impact resistance: The added carbon fiber makes PC-CF more resistant to impacts, making it ideal for environments where parts are subjected to stress or vibration.

- Static dissipation: The anti-static properties help reduce the buildup of static electricity, providing enhanced protection for sensitive electronics.

PC-CF is a preferred material for automotive and industrial applications requiring parts that can endure heavy use, making it a top choice for manufacturing aids, housing components, and protective covers.

3. PAHT-CF (High-Temperature Polyamide with Carbon Fiber)

PAHT-CF is a high-temperature polyamide (PA) composite that includes carbon fiber, giving it impressive chemical resistance, low moisture absorption, and high dimensional stability. This combination provides a strong, heat-resistant material that performs well under stress and is ideal for high-temperature applications.

- High-temperature tolerance: PAHT-CF can withstand temperatures up to 150°C, making it suitable for applications with high thermal exposure.

- Chemical resistance: This material is highly resistant to many chemicals, enhancing its durability in harsh environments.

- Low hygroscopicity: PAHT-CF absorbs minimal moisture, making it dimensionally stable and less likely to warp, which is ideal for humid or high-moisture environments.

- Easy to process: PAHT-CF is relatively easy to work with in FGF printing, making it a practical choice for industrial applications.

PAHT-CF is popular in automotive and aerospace sectors where parts may need to withstand high temperatures and corrosive environments, as well as in applications such as engine components and housing that require enhanced durability.

Applications for Carbon Fiber Reinforced 3D Printed Parts

Carbon fiber reinforced 3D printed parts offer a unique combination of strength, light weight, and resistance to impact, heat, and chemicals. These properties make them suitable for a variety of applications where traditional 3D printing materials may fall short.

1. Automotive and Aerospace

In the automotive and aerospace industries, carbon fiber reinforced parts are ideal for applications requiring high strength-to-weight ratios and temperature resilience. For example:

- Engine components: PAHT-CF and PC-CF can be used to create parts that withstand high temperatures and vibrations.

- Replacement for aluminum: Lightweight yet strong carbon fiber composites can serve as a substitute for certain machined aluminum parts, reducing weight while maintaining durability.

2. Manufacturing Aids and Industrial Components

The durability and flexibility of carbon fiber reinforced materials make them suitable for manufacturing aids such as jigs, fixtures, and tooling. These parts require high strength, static dissipation, and impact resistance, which can be achieved with materials like ABS-CF and PC-CF.

- Tooling and fixtures: ABS-CF offers good static dissipation and durability, which is useful for fixtures that interact with electronics.

- Protective housings and covers: PC-CF provides strength and impact resistance, ideal for parts that need to protect sensitive equipment or endure heavy use.

3. Electronics and EMI Shielding

For electronics applications, ABS-CF’s EMI shielding properties provide a solution for protecting sensitive electronic equipment from electromagnetic interference. Parts made from ABS-CF can shield sensitive devices, offering a balance of conductivity and static dissipation.

4. Medical and Consumer Products

The combination of strength and chemical resistance makes carbon fiber reinforced 3D printing materials useful in medical devices and consumer goods. These applications often require materials that can withstand exposure to chemicals, be lightweight, and maintain structural integrity under stress.

- Wearable medical devices: TPU-based carbon fiber materials provide flexibility and resilience, making them comfortable and durable for medical applications.

- Sporting equipment and consumer goods: Carbon fiber reinforced parts add durability and impact resistance, perfect for products that need to handle rough use or high stress.

Conclusion

Carbon fiber reinforced pellets in FGF 3D printing represent a significant advancement in additive manufacturing, offering an effective solution for creating high-performance parts with enhanced strength, light weight, and resilience. Whether for automotive, aerospace, industrial, or consumer applications, carbon fiber composites like ABS-CF, PC-CF, and PAHT-CF enable the production of durable parts that rival traditional manufacturing materials.

As 3D printing continues to evolve, carbon fiber reinforced pellets are poised to unlock new applications and further solidify FGF technology as a viable solution for high-stress and demanding environments. For anyone looking to harness the potential of 3D printing in industrial applications, carbon fiber reinforced materials offer a powerful combination of functionality and reliability.