Table of Contents

3D printing is transforming industries, and dentistry is no exception. Dental 3D printing is revolutionizing dental practices, enabling digital workflows that enhance efficiency and improve patient outcomes. Let’s delve into how 3D printers are making significant advancements in the field of dentistry, specifically in the production of dental crowns.

Is 3D Printing Used in Dentistry?

Yes, 3D printing is extensively used in dentistry. Dental 3D printers have become indispensable tools for modern dental practices, enabling the creation of highly precise dental models, crowns, bridges, and other dental appliances. The shift from traditional methods to digital workflows has brought about remarkable improvements in the speed, accuracy, and cost-effectiveness of dental procedures.

Traditionally, creating dental crowns and other appliances involved multiple steps, including taking molds of the patient’s teeth, creating a physical model, and then manufacturing the crown through a labor-intensive process. This method often resulted in prolonged treatment times and a higher margin for error. With the advent of dental 3D printing, these challenges are effectively addressed.

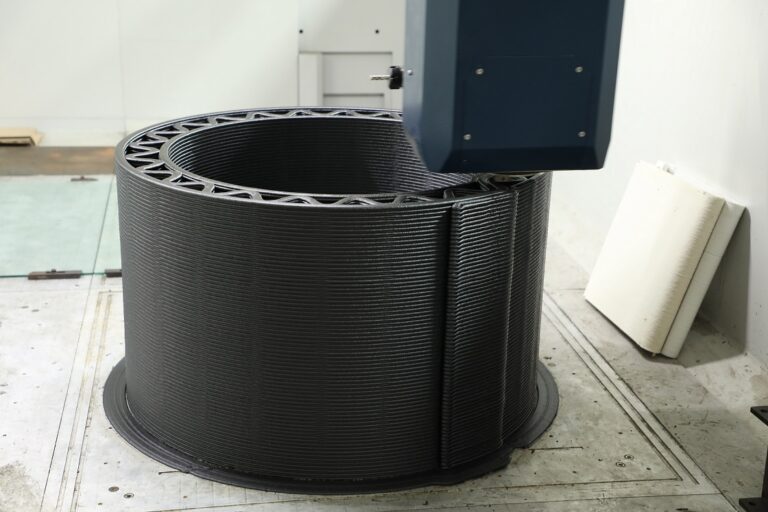

3D printing technology allows for the digital design and direct manufacturing of dental appliances. Dentists can use intraoral scanners to capture detailed images of the patient’s teeth, creating precise digital models. These models are then used to design crowns and other dental restorations with exact specifications. The designs are sent to a dental 3D printer, which fabricates the items with incredible precision.

Can Dental Crowns Be 3D Printed?

Absolutely. Dental crowns can be 3D printed with remarkable precision and efficiency. The process involves scanning the patient’s teeth to create a digital model, which is then used to design the crown. This digital design is sent to a dental 3D printer, which builds the crown layer by layer using biocompatible materials. This method ensures a perfect fit and reduces the time required for adjustments and fittings.

3D printing dental crowns streamline the entire process, making it faster and more reliable than traditional methods. The precision of 3D printing allows for the creation of crowns that fit perfectly with minimal adjustment. This not only enhances patient comfort but also reduces the number of visits needed to complete the procedure.

Moreover, 3D printing allows for on-demand production of dental crowns. This means that dentists can produce crowns quickly and efficiently, responding to patient needs promptly. The speed and accuracy of 3D printing reduce the overall time required for crown placement, which is particularly beneficial for patients who require immediate dental restorations.

What Material Are 3D Printed Crowns Made Of?

3D printed dental crowns are typically made from Temporary Restoration Resin. This material is a bio-compatible, tooth-colored resin specifically designed for temporary crown and bridge restorations, inlays, onlays, and veneers. Here are some key features of Temporary Restoration Resin:

- Pressure and Impact Resistance: Temporary Restoration Resin offers strong durability under bite pressure, making it ideal for temporary crowns and bridges that need to withstand the forces of chewing.

- Wear and Corrosion Resistance: The material is resistant to wear and corrosion, ensuring longevity and reliability of the dental restorations.

- Dimensional Stability: The resin provides excellent dimensional stability, allowing for a precise fit with minimal shrinkage or distortion during the printing process.

- Color Stability: Maintaining natural tooth aesthetics over time is crucial for patient satisfaction. Temporary Restoration Resin is available in five shades to match the patient’s natural teeth, and it maintains high color stability to ensure a natural look.

What Are the Advantages of 3D Printing Dental Crowns in Dentistry?

Accuracy: 3D printed dental crowns are highly precise, ensuring a perfect fit and reducing the need for adjustments. The digital design process allows for meticulous planning and customization, resulting in crowns that match the patient’s dental anatomy accurately.

Efficiency: The digital workflow significantly reduces the time required to produce and fit dental crowns, leading to faster treatment times and increased patient turnover. Traditional methods can take several weeks to produce a crown, while 3D printing can complete the process in a matter of hours.

Improved Outcomes: Patients benefit from crowns that are not only comfortable and aesthetically pleasing but also durable and long-lasting. The precision and quality of 3D printed crowns result in better-fitting restorations that require fewer adjustments and repairs over time.

Cost-Effective: By reducing the time and materials required for crown production, 3D printing can lower the overall cost of dental treatments. This makes high-quality dental care more accessible to a broader range of patients.

Customization: 3D printing allows for the creation of highly customized dental crowns tailored to the specific needs of each patient. This level of customization enhances the overall effectiveness of the treatment and improves patient satisfaction.

Which 3D Printer Is Best for Dental Crowns?

Piocreat offers top-of-the-line dental 3D printers designed to meet the needs of modern dental practices. Two standout models are:

- Top cost-effective resin 3D printer for dental industries

- 29μm Pixel Size: Delivers unmatched print clarity and detail. The high resolution ensures that even the smallest details of the crown are accurately reproduced.

- Heating Chamber: Ensures consistent temperature for optimal printing conditions. This feature helps in maintaining the quality of the printed crowns by preventing temperature fluctuations that could affect the resin.

- Automatic Feeding: Simplifies the printing process and reduces manual intervention. This feature enhances the efficiency of the printing process, allowing dental professionals to focus on patient care.

- Stable Z-axis Structure: Provides precise and reliable prints. A stable Z-axis is crucial for producing high-quality dental crowns with consistent accuracy.

- Excels in dentistry with unmatched productivity

- Speeds up to 80mm/h: Ensures quick production of high-quality prints. The high speed of the D150 allows for the rapid creation of dental crowns, reducing the waiting time for patients.

- High Speed Release Film: Enhances the efficiency of the printing process. This feature helps in speeding up the printing process by reducing the time required for layer separation.

- Adjustable Light Intensity: Ranges from 6000-20000uw/cm2 for flexible printing conditions. The adjustable light intensity allows for the optimization of printing conditions based on the specific requirements of the resin and the dental application.

- Light Engine Life 30,000+ Hours: Offers long-lasting performance for busy dental practices. The durability of the light engine ensures that the D150 can handle high-volume printing tasks without compromising on quality.

Wrapping Up

The 3D printer for dental crowns is a game-changer in the dental industry, offering precision, efficiency, and improved patient outcomes. Whether you’re creating temporary crowns or intricate dental models, 3D printing technology is paving the way for the future of dentistry. With advanced printers like the DJ89 PLUS and D150, Piocreat is at the forefront of this dental revolution, providing professionals with the tools they need to deliver the best care possible.

By embracing dental 3D printing, dental practices can significantly enhance their workflows, offering patients superior care and more efficient treatments. The future of dentistry is here, and it’s being shaped by the incredible advancements in 3D printing technology.