FGF Pellet 3D printing is the next evolution in 3D printing technology. These dirrect-drive pellet extrusion-based printers can print using virgin or recycled pellets, flakes, or regrind materials, bringing us closer to the dream of a circular econdmy.

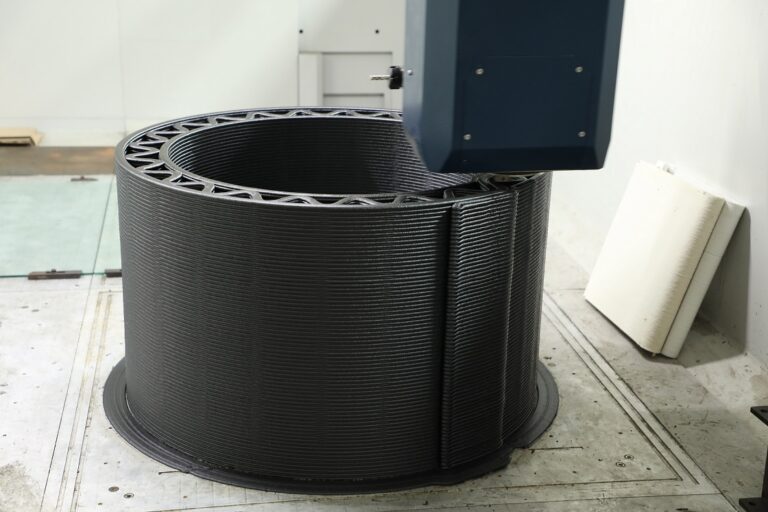

G5 Ultra 3D printer promotes sustainability through its granules/pellets-based open material system, enabling the use of recycled and eco-friendly materials, reducing waste, and championing circular economy principles, empowering businesses to make environmentally responsible choices for a more sustainable future.

Pellets are less energy intensive to produce, easier to transport in bulk (meaning lower transport emissions), and don’t come in wasteful plastic spools. In addition, there are many recycled pellets on the market, and if you have the means to shred your own plastics, you can also recycle your own waste into feedstock.

In this case, we’re using PLA recycled material, a reusable and degradable eco-friendly material. But the potential of G5 Ultra isn’t limited to this, It can print a variety of recycled materials. With its ability to heat up to 400°C, the G5 Ultra Pellet 3D Printer excels in processing a wide range of thermoplastics and composites. This flexibility allows for experimenting with various pellets, including PA-CF, PA-GF, PC-CF, PLA, rPLA, PETG-GF, ABS, PS, GPPS, PP-GF, and more.

Customer Stories: Outdoor Planting Pots from Recycled Materials

In collaboration with PioCreat 3D, TRASHAUS successfully turned recycled materials into outdoor planting pots. During the selection process, traditional materials posed challenges. Wood, while easy to cut, lacked weather resistance and rotted quickly in outdoor environments. Concrete, though durable, was heavy and cumbersome to transport.

“Using recycled plastics and breakthrough printing technology, we were able to customize large and small triangular flower pots of varying heights that are both beautiful and practical,” explains Vans. “We reused 1,000KG of recycled home appliances and electronic equipment plastics.”

The flexibility and durability of the recycled plastic pots demonstrated the practical applications of TRASHAUS’s approach. The collaboration with PioCreat 3D showcased the advantages of using the G5Ultra, which utilizes cost-effective thermoplastic pellet feedstocks. This method reduced material costs by over 60% and promoted a sustainable production process.