Table of Contents

3D printing has introduced a sustainable and innovative way to repurpose waste plastic, reducing the environmental impact of traditional manufacturing processes. Recycled plastics are emerging as popular materials for 3D printing, providing users with eco-friendly options to create custom objects while reducing plastic waste in landfills. This trend, supported by advanced 3D printing technologies such as Fused Granulate Fabrication (FGF), offers both economic and environmental advantages.

In this blog post, we’ll explore the feasibility of using recycled plastic for 3D printing, the types of sustainable materials available, and how this approach contributes to environmental conservation. We’ll also address common questions about using recycled plastics in 3D printing and provide recommendations on the best equipment for sustainable printing.

Can Recycled Plastic Be Used for 3D Printing?

Yes, recycled plastic is an excellent material for 3D printing, especially for users interested in sustainability. Companies now offer 3D printing services using recycled plastics to create custom objects, from furniture and art to functional prototypes. This approach not only reduces the amount of waste sent to landfills but also lowers the production cost, as recycled plastic is often less expensive than newly manufactured plastic.

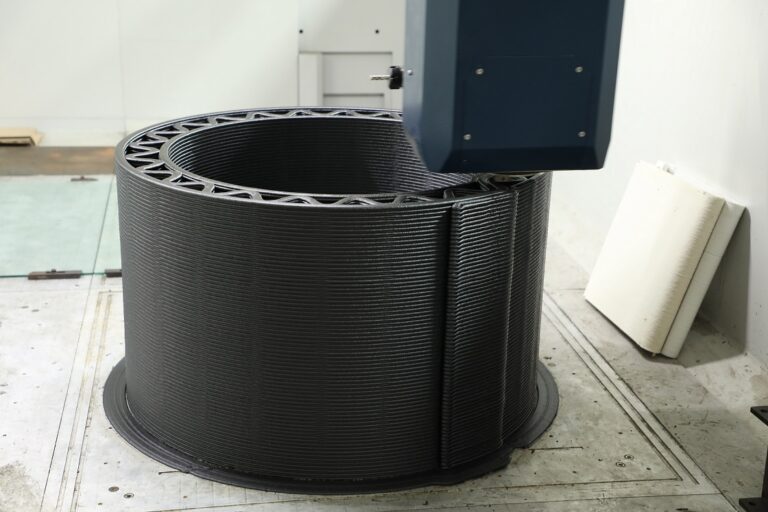

The adoption of recycled plastics in 3D printing has increased significantly with the development of extrusion-based technologies, like FGF, that allow users to work with shredded plastic pellets instead of filament. This technology enables the creation of both small and large objects with minimal waste, making it a financially and environmentally viable solution.

What Sustainable Plastics Are Being Used in 3D Printing?

Several types of recycled plastic are suitable for 3D printing, each offering unique properties that make them versatile for different applications. Here are some commonly used sustainable plastics for FGF 3D printing:

1. ABS (Acrylonitrile-Butadiene-Styrene)

ABS is a widely used thermoplastic known for its mechanical strength and wear resistance, making it ideal for structural and functional parts. It is often sourced from recycled electronics, such as discarded keyboards and mice, giving these items a second life in the form of durable 3D-printed products. ABS’s toughness makes it suitable for creating parts that require durability, like functional prototypes and industrial components.

2. PLA (Polylactic Acid)

PLA is a biodegradable plastic derived from renewable resources, such as corn starch, making it a popular choice for eco-friendly 3D printing. PLA is known for its low melting temperature, which minimizes energy consumption during printing. It has minimal deformation, making it suitable for creating detailed models and art pieces. Additionally, PLA is relatively easy to work with, even for beginners, and can be recycled from agricultural waste or industrial by-products, reducing the need for new petroleum-based materials.

3. PET (Polyethylene Terephthalate)

PET, commonly used in plastic bottles, is one of the most accessible recycled materials for 3D printing. Recycling PET bottles into printing material helps to divert plastic waste from landfills, providing a low-cost, readily available option. PET is flexible, strong, and resistant to moisture, making it well-suited for a variety of applications, including furniture, home decor, and educational tools. Users can even collect their own plastic bottles, convert them into printing materials, and create custom objects, making PET an ideal choice for sustainable, small-scale projects in studios, schools, and labs.

4. EVA (Ethylene Vinyl Acetate)

EVA is an elastomeric polymer known for its soft, rubbery texture, which is useful for products requiring flexibility and cushioning. Commonly used in medical devices and sports equipment, EVA’s flexibility and durability make it ideal for functional parts that require some level of shock absorption or adaptability. Recycling EVA helps reduce the demand for virgin elastomeric materials and is useful for creating custom grips, footwear components, and protective gear.

5. PC (Polycarbonate)

Polycarbonate (PC) is a high-performance plastic known for its strength, transparency, and heat resistance. It is typically recycled from items like CDs, DVDs, and clear plastic containers. Due to its robustness, PC is well-suited for creating engineering-grade parts that require high impact resistance and stability under temperature fluctuations. Its high transparency makes it a preferred choice for applications requiring visibility, such as protective covers, light casings, and display elements.

Each of these materials can be sourced as either recycled or virgin, depending on the desired properties of the final product. Proper treatment and purification are essential to ensure that recycled materials are free from impurities, which helps to maintain quality and durability during printing.

Can I Mix Shredded Recycled Plastic with Virgin Pellets?

Yes, mixing recycled plastic with virgin pellets is a viable approach in 3D printing, particularly when looking to balance sustainability with specific mechanical properties. The ratio of recycled to virgin pellets will affect the characteristics of the printed object, so experimentation is key to achieving the desired quality and performance.

For example, adding virgin plastic pellets can enhance the strength, flexibility, or durability of the print, while still reducing the total amount of new plastic required. This mixed approach allows for greater control over the final product and makes recycled 3D printing accessible for applications where pure recycled plastic might not provide the required quality.

Can You 3D Print Furniture Out of Recycled Plastic?

Yes, recycled plastic is an excellent material for creating 3D-printed furniture. This approach is not only sustainable but also enables designers to create custom, functional pieces that have a positive impact on collective consumer waste. Recycled plastic furniture is highly durable, weather-resistant, and easy to maintain, making it ideal for both indoor and outdoor use. By reimagining waste plastic as a valuable resource, this process contributes to a circular economy, where waste is continuously repurposed into new products.

Collaborations, like those between PioCreat 3D and TRASHAUS, have demonstrated the potential of recycled plastic furniture. Through this partnership, they transformed over 1,000 kilograms of waste from home appliances into large and small triangular flower vases, showcasing the versatility and aesthetic potential of recycled 3D-printed furniture.

Best 3D Printer for Recycled Plastic: PioCreat G5Ultra

For those looking to begin sustainable 3D printing with recycled plastic, the PioCreat G5Ultra is a highly recommended option. This desktop pellet 3D printer offers high-speed printing and industrial-grade capabilities, making it suitable for various sustainable projects, including custom furniture and eco-friendly prototypes.

Key Features of the PioCreat G5Ultra:

- Build Volume: 500×500×400mm, suitable for small to medium-sized objects

- Nozzle Temperature: Capable of reaching up to 400℃, accommodating a wide range of thermoplastics, including recycled materials

- Hot Bed Heating: Heats up to 120℃, providing optimal adhesion and reducing warping for high-quality prints

- Screw Extruder Design: Designed to handle both recycled and virgin plastic pellets, making it versatile for eco-friendly projects

The G5Ultra’s compatibility with recycled materials and pellet feedstock allows for cost-effective, sustainable printing solutions, making it an excellent choice for anyone interested in 3D printing with a minimal environmental footprint.

Environmental and Economic Benefits of 3D Printing with Recycled Plastic

Using recycled plastic in 3D printing offers a range of benefits, from reducing waste to lowering production costs. Here are some of the key advantages:

Reduced Environmental Impact

Every kilogram of recycled plastic used for 3D printing reduces the need for virgin plastic, which helps conserve resources and decrease the environmental footprint associated with plastic production. Additionally, by reusing plastic waste, this approach helps to reduce the amount of plastic that ends up in landfills and oceans.

Cost Savings

Recycled plastic pellets are generally less expensive than virgin plastic filament, making FGF 3D printing a more affordable option for creating high-quality items. This cost savings is especially beneficial for businesses and educational institutions that aim to integrate sustainability into their practices without increasing expenses.

Versatility Across Applications

Recycled plastics can be used in a wide range of applications, including furniture, home decor, and functional prototypes. This versatility makes recycled plastic a valuable resource for those looking to create durable, functional, and environmentally conscious products. From artists to engineers, anyone can explore innovative designs with minimal waste.

Begin Your Journey Towards Sustainable 3D Printing

If you’re ready to start sustainable 3D printing with recycled plastics, here are some steps to guide you:

- Choose a Pellet-Compatible Printer: Select a 3D printer, like the PioCreat G5Ultra, that supports pellet feedstock and can handle recycled materials.

- Source Recycled Plastic: Recycle plastic waste from your own household, or purchase shredded recycled plastic from a certified supplier for higher quality.

- Experiment with Ratios: Experiment with different ratios of recycled and virgin plastic to find the best balance for your projects.

- Start Small: Begin with simple projects, such as planters, stools, or small decor items, to gain experience before advancing to more complex designs.

Hope for the Future: A Greener Tomorrow with Recycled Plastic 3D Printing

As environmental awareness grows, 3D printing with recycled plastic offers a promising step toward sustainable manufacturing. FGF technology and pellet-based 3D printing provide an efficient, eco-friendly way to repurpose waste plastic, reducing environmental impact while supporting a circular economy.

Whether you’re creating furniture, prototypes, or art pieces, choosing recycled plastic in 3D printing empowers you to make a positive impact, one layer at a time. By embracing sustainable practices, we can pave the way for a greener, more responsible future.