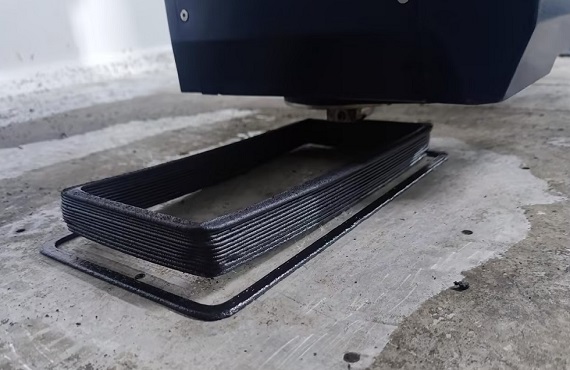

3D printed molds are transforming the manufacturing industry. FGF 3D printing technology can deliver high-performance plastic molds that produce quality parts while drastically reducing lead times and labor costs compared to traditional methods. Piocreat 3D offers innovative 3D printing solutions for large molds used in thermoforming heavy gauge plastics.

Reduce cost and Shorten Lead Times for Large Molds

The cost of pellets is 65% to 90% lower than that of the same plastic filament.

Enjoy speeds up to 10X faster than conventional filament extrusion 3D printing, drastically reducing project lead times.

Achieve optimal material performance using raw materials and ensure enhanced performance of printed components through excellent quality.

The G12 Pellet 3D Printer is a large-format pellet extrusion printer capable of printing medium-to-large format parts.

Suitable for a variety of composite materials, including ABS-CF PC-CF PETG-GF PAHT-CF, etc.

It offers versatile slice thicknesses (0.2-1.5mm) and nozzle sizes (0.6-4mm), enabling both fine details and high flow rates (up to 3kg/h).

It ensures uniform extrusion force and achieves industrial-grade printing accuracy.

The G40 Pellet 3D Printer is a versatile industrial additive and CNC five-axis manufacturing integrated Machine.

Suitable for a variety of composite materials, including ABS-CF PC-CF PETG-GF PAHT-CF, etc.

The G40 advances extrusion efficiency with its high-flow, 3-8mm screw nozzles, achieving high flow rates (up to 25kg/hr) and maintaining quality.

Its A axis offers +120° and the C axis +320° rotation, ensuring flexibility and top performance

By integrating carbon fiber into the printing process, these materials can produce parts that are stronger and lighter than those made with traditional materials.

Copyright © 2025 PioCreat 3D Technology Co., Ltd. All Rights Reserved.