Table of Contents

The intersection of 3D printing and architecture is creating ripples of transformation across the construction industry. From conceptual prototypes to full-scale buildings, 3D printing has introduced a faster, more efficient, and sustainable approach to architectural design and construction. As architects push the boundaries of what is possible, 3D printing is helping to create complex forms, reduce waste, and enhance cost-effectiveness. In this blog, we will explore the growing application of 3D printing in architecture, its current uses, its benefits, and the exciting future it holds.

3D Printing in the Architecture Industry

Over the past decade, 3D printing has moved from a niche technology to a widely accepted tool in architecture. It is primarily used to print architectural models, prototype building elements, and even entire structures. The ability to precisely produce complex geometries that would otherwise be impossible with traditional manufacturing techniques has made 3D printing indispensable in many architectural firms.

The appeal of 3D printing lies in its versatility. Architects can rapidly produce models, functional parts, and components, as well as experiment with various designs and materials. This enables innovation in structural forms and allows architects to showcase intricate details in their projects that would otherwise be difficult to present through conventional means.

3D Printing Applications in Construction

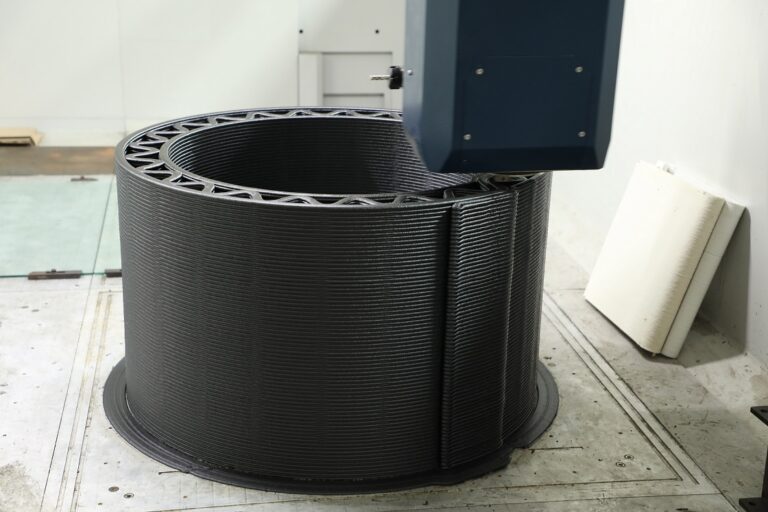

Beyond its role in design, 3D printing is actively being used in construction. 3D-printed structures have gained significant attention in recent years, with innovative construction techniques emerging to build homes, offices, and even bridges. The technology allows construction companies to print entire sections of buildings on-site, drastically reducing both construction time and labor costs. Furthermore, the flexibility of 3D printing enables the use of eco-friendly materials, contributing to more sustainable building practices.

Creating Prototypes

One of the early and most widespread applications of 3D printing in architecture is the creation of prototypes. Traditionally, producing physical prototypes was a time-consuming and expensive process, often requiring external resources. With 3D printing, architects can quickly produce accurate, detailed prototypes of buildings, facades, or even interior elements, such as furniture. This allows for easy testing of form, scale, and material usage before committing to full-scale construction.

Advantages of creating prototypes with 3D printing include:

- Rapid production:Prototypes can be printed within hours or days, depending on complexity, compared to weeks with traditional methods.

- Cost-effectiveness:Reduces the need for outsourced modeling, saving time and expenses.

- Design accuracy:3D printing allows for greater precision in architectural designs, leading to more refined outcomes.

Creating Parts

3D printing is also used to create specific parts for building structures, such as customized joints, brackets, and other architectural elements that would otherwise need to be manufactured using complex methods. By printing these parts directly, architects have more control over the design and quality of each component. It also offers the freedom to experiment with organic and non-traditional shapes.

Creating Architectural Models

Architectural models are essential for visualizing concepts, designs, and structural integrity before building starts. Using 3D printers, architects can now produce highly detailed, realistic models that accurately represent the final building. These models are used to convey design intent, refine construction plans, and communicate ideas more effectively to clients and stakeholders.

Compared to traditional handcrafted models, 3D-printed architectural models have several key benefits:

- Speed:The process of model-making is expedited, allowing multiple iterations in a short time.

- Precision:Architects can achieve intricate designs that traditional methods may not handle effectively.

- Cost-efficiency:3D printing requires less manual labor, reducing the overall cost of creating detailed models.

Landscape Architecture

3D printing isn’t just limited to buildings. It’s also finding applications in landscape architecture. For example, architects and designers use 3D printers to create scaled-down topographical models of landscapes, parks, and outdoor spaces. These printed models help designers visualize how various elements, such as trees, water features, and pedestrian pathways, will interact with one another in real life.

Additionally, landscape architects can explore innovative designs, like green walls, using 3D printing to prototype sustainable urban environments. The technology can aid in assessing the environmental impact of construction projects, allowing architects to make informed decisions about site planning and land usage.

How 3D Printing Has Advanced Architecture

The adoption of 3D printing in architecture has brought about numerous benefits, reshaping the way structures are designed and built. Here are some key advancements:

Less Waste

Traditional construction processes often result in substantial material waste, particularly when working with complex forms that require customized cutting and shaping. 3D printing, by contrast, is an additive process, meaning that materials are only used where necessary. This significantly reduces waste and ensures that resources are used more efficiently.

Recycling

3D printing has also opened up new possibilities for recycling materials in construction. For example, recycled plastics, glass, or other materials can be repurposed into filament or pellets for 3D printing. This not only reduces environmental waste but also lowers the cost of construction materials, making sustainable building more feasible and attractive to architects.

Cost-effectiveness

One of the most appealing aspects of 3D printing in architecture is its ability to drive down costs. By reducing the need for labor-intensive, traditional manufacturing methods, 3D printing can produce complex structures at a fraction of the cost. Furthermore, creating multiple design iterations with 3D printing is much more affordable, allowing architects to experiment and refine their designs without exceeding their budget.

Example: Using 3D printing for rapid prototyping allows architects to test multiple designs, tweak them as needed, and reprint the revised versions at minimal additional cost.

Quick Production

The speed of 3D printing compared to traditional construction methods is another major advantage. In the past, creating architectural models or prototypes could take weeks or even months. With 3D printing, these timelines are drastically reduced, allowing architects to quickly produce models, test designs, and move forward with construction plans.

Example: The speed at which 3D printing can produce architectural models means that designers can make changes and print updated models in a fraction of the time it would take using traditional methods.

The Future of 3D Printing in Architecture

As 3D printing technology continues to evolve, its applications in architecture are poised to expand even further. Here are some exciting trends shaping the future:

The Use of Recycled Materials for 3D Printing

As sustainability becomes an increasingly important consideration in architecture, the use of recycled materials for 3D printing is expected to grow. Architects and builders are exploring ways to repurpose waste materials, such as plastic bottles, old tires, and other industrial byproducts, into 3D printing materials. This shift towards eco-friendly materials could help reduce the environmental impact of construction projects while promoting circular economy principles.

On-demand and Just-in-time Construction

The future of construction may also see the rise of on-demand, or just-in-time, 3D-printed structures. Rather than producing building components in bulk, construction companies could print parts or entire structures on-site as needed. This could revolutionize the construction industry by reducing storage costs, minimizing waste, and accelerating the building process.

Best 3D Printers for Architectural Models

For architects looking to invest in 3D printing technology, there are several printers that stand out for their performance, versatility, and capacity to handle large-scale projects. Two of the best options are the G12 Pellet 3D Printer and the G40 Pellet 3D Printer.

G12 Pellet 3D Printer

- Large Scale, Built Volume:1200×1000×1000mm

- Nozzle Temperature:Up to 450℃, enabling it to handle high-performance materials.

- Rapid Heating of Hot Bed:Up to 120℃, reducing downtime between prints.

- High Flow Screw Extrusion:Capable of printing medium-to-large format parts with ease.

- Powerful Servo Motor:Provides the necessary torque for precise and high-quality prints.

The G12 Pellet 3D Printer is a versatile and large-format printer ideal for producing architectural models, furniture, or structural parts.

G40 Pellet 3D Printer

- Large Scale, Built Volume:3725×2500×1330mm

- Workbench Design:Allows for more stability and control during large-scale prints.

- CNC Five-axis Head:Offers enhanced precision and the ability to print complex, multi-directional components.

- High Flow Screw Extrusion:Ensures efficient printing of large-format parts.

The G40 Pellet 3D Printer is PioCreat’s largest industrial printer and is capable of printing entire sections of buildings, making it a powerful tool for large-scale architectural projects.