3d printing never stops surprising with the different ways to approach design and modeling.

In this customer case, we’ll discovering new esthetic through materials and their features. Also is a great example of how Additive Manufacturing can be an incredibly powerful tool for companies to create unique designs that bring together beauty, quality and sustainability.

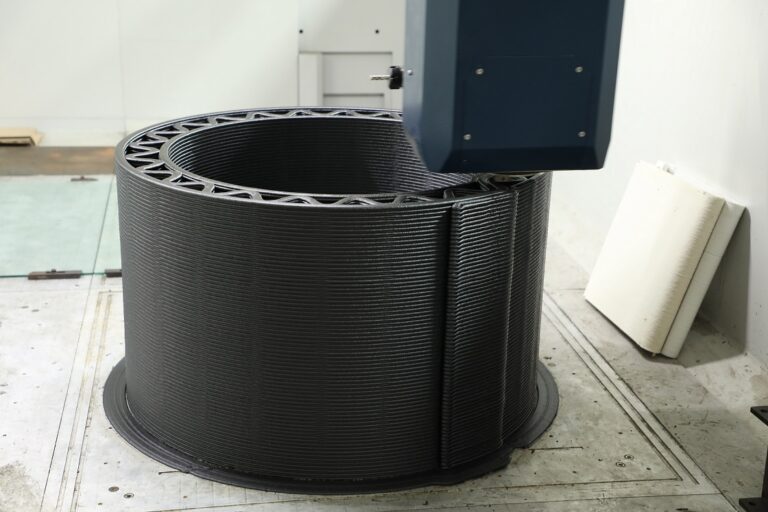

Printed using Piocreat G12 pellet 3D printer, the decoration flowers was designed with light and shadow interplay in mind, made to look good both during the day and at night while at the same time fostering a warm and inviting atmosphere. It was printed using PETG recycled material, turning plastic waste into high quality build material for 3d printing.

The G12 boasts impressive specifications, featuring a substantial printing size of 1200 x 1000 x 1000 mm, providing ample space for large-scale projects. Equipped with a single screw nozzle design, the printer ensures uniform extrusion force, facilitating high-quality prints with precision and consistency across various materials.

With a nozzle temperature reaching up to 450°C and a bed temperature of ≤150°C, the G12 accommodates a diverse range of materials, including PLA, PETG, ABS, TPU, and composite materials. The G12 Pellet 3D Printer represents a huge leap in cost-effective industrial additive manufacturing, redefining the landscape with its cost-effectiveness, speed, and environmental consciousness.

With its advanced features, expansive printing capabilities, and commitment to sustainability, the G12 sets a new standard for industrial-grade 3D printing technology, empowering industries to innovate and create with unparalleled efficiency and precision.